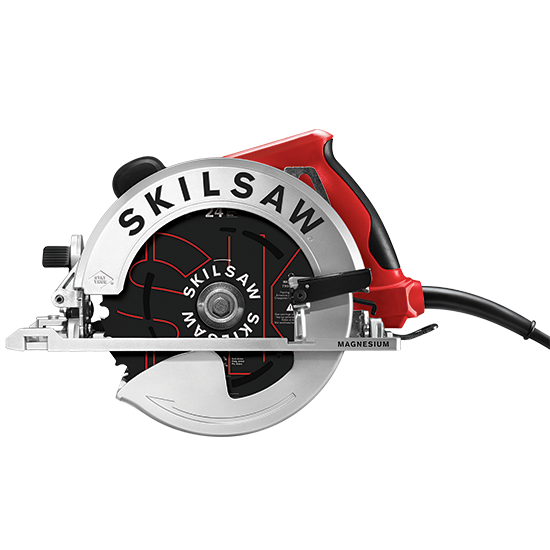

SKILSAW Circular Saw

SKILSAW’s Blade-Right and Blade-Left Sidewinders

This is a review of two of SKILSAW’s blade-right and blade-left sidewinders, specifically the blade-right model SPT67WMB-01 and the blade-left model SPT67M8-01. Both are corded models and, BLUF, I very much like them both. Now, before I get into why I like these particular coded sidewinders, let me explain why I’m partial to sidewinders and lean towards corded saws in some cases.

Worm Drive vs. Direct Drive

Wormies built the west coast and sidewinders built the east coast, and the pros and cons of worm drive vs. direct drive (sidewinder) circular saws has certainly been written about a great deal. I grew up with sidewinders; here are my two cents and perspective.

While it’s true that worm-drive saws deliver more power, I seldom find my sidewinders to be underpowered for normal jobs. The better line-of-sight that the typically blade-left worm-drive saws provide is actually not so simple — I address the complexity of this subject in a companion article here. Conversely, sidewinders are often said to support the weight of the motor better during cuts. Again, this is not so simple; see the same companion article for details.

Worn drive fans will often say that the extra weight helps you keep truer to a cut line than a sidewinder, while sidewinder fans say they are more agile. These differences are small at best. Worm-drive aficionados like to claim that a wormie, because of its large, oil-bathed worm gear, will have a longer service life than a sidewinder. This is probably true, but a quality sidewinder will also last a long time, and if they’re your preference then paying a few dollars a year to use the tool you’re comfortable with is the right choice.

The extra weight of worm-drive saws is what I find hard to get used to. While there are some worm-drive saws that weigh little more than a typical pro-level sidewinder (SKILSAW makes one, in fact), it’s the weight distribution that I find awkward. On a wormie all the weight is in front of your hand, requiring you to continually lever the saw into position with your forearm muscles. Sidewinders, by contrast, have their weight directly underneath the hand, making them much less strenuous to use.

Corded vs. Cordless Saws

I know the world is going cordless, and I’m really glad to see so many tools come cordless these days. But there are a few tools that I still like corded if the situation allows. My reasons do not include power. Up to a few years ago, you could argue that corded tools provided more power than cordless ones, but that’s no longer true, even with saws.

I generally like corded tools in places where I’m set up to do a job. On most jobs of any size, you set up a cutting station and do your cutting there, running the cut pieces to the installation location. True, I never have to worry about changing batteries, but the real issue with batteries is that they negatively affect the saw’s balance and add weight. If there’s power available and I can set it up, I go corded.

Of course, I have cordless circular saws for out-of-position cutting (rafters or on a roof are good examples, door and window cut-outs on standing walls are another) and for onesey-twosey cuts.

SKILSAW Circular Saw As The Standard

SKILSAW Power Tools was founded in 1924, by Edmond Michel in Chicago. In 1937 the worm drive SKILSAW Model 77 was introduced and this (and its successors) was the saw that built the homes west of the Mississippi during the building boom of the mid-century. The framers who fed their families with this saw understandably developed a real attachment to it. For them, it is the ONE TRUE saw, brought down from Mount Sinai by Moses himself.

A competitor on the east coast, in an effort to get around Michel’s patents, developed the direct-drive saw (AKA “sidewinder”). It became the standard east of the Mississippi.

Following WWII the company changed its name to SKIL and branched out into other tools, some addressing the DIY market, which confused the company’s reputation in the pro market. In 2014 SKIL rebranded, making SKILSAW the brand serving the professional construction market and SKIL the brand serving the DIY market. A few corporate reshuffles later and today Chevron Ltd. Owns SKIL.

Also in 2014 SKILSAW introduced two pro-grade sidewinders. Today they offer five models (for cutting wood), including the two reviewed here, and of course, they continue to sell their iconic worm drive saws in a few different models.

SKILLSAW Cuircular Saw Blade-Right With Brake SPT67WMB-01

While SKILSAW makes several blade-right sidewinders, including one that weighs a little less, this model has a brake. Specs:

- Motor brake

- All magnesium

- 15 amp dual-field motor

- Accessible brushes

- 0 to 56-degree bevel capability

- 10-foot cord

- No load speed of 5300 rpm

- 45-degree bevel detent

- 9H x 12.75L x 9.75W inches

- 2 7/16-inch cut depth at 90 degrees

- 180 days no-questions returns

- One-year limited warranty

- 10 pounds and change

- $169 street price

SKILLSAW Circualr Saw Blade-Left SPT67M8-01

This is currently SKILSAW’s only blade-left corded sidewinder. Specs:

- All magnesium

- 15 amp dual-field motor

- 0 to 56-degree bevel capability

- 10-foot cord

- No load speed of 5300 rpm

- 45-degree bevel detent

- 9H x 12.5L x 9W inches

- Approximately 9 pounds

- 2 7/16-inch cut depth at 90 degrees

- 180 days no-questions returns

- One-year limited warranty

- $130 street price

SKILLSAW Circular Saw | Evaluation

Rob took a look at the SKILSAW SPT67WL-01 back when SKILSAW entered the sidewinder market and liked it a lot. In fact, SKILSAW still makes this model. The saws I’m looking at here are follow-on models, and my impressions of these later models echo many reviews of the original models back in 2014/2015. SKILSAW isn’t just churning out new models for the sake of something new – they are keeping their tried-and-true models and coming out with newer models when they offer something new that their pro-market wants.

Now, Rob and the crew at ToolBoxBuzz do the best job in the industry with their head-to-head comparisons of tools. There they measure all kinds of performance metrics with very clever test rigs and objective criteria. My own evaluations, however, of necessity, aren’t that elaborate – they are more intuitive, personal, and functional.

Tool Review Criteria

In evaluating a tool I look at these four things:

- How does it feel in the hand?

- How does it feel in use?

- Does it do what I want it to do?

- What features make it easy or difficult to use?

Both of these saws are similar so I’ll address them together in answering those questions.

How Do They Feel In The Hand?

How a tool feels when you pick it up isn’t as important as how the tool performs, but it still matters. High-quality tools feel solid and bomb-proof; cheap tools feel tinny and plastic-ey. This affects your confidence in the tool and how you feel about using it. I have written before that “good tools are a joy to use”.

With regard to this SKILSAW blade-right and blade-left sidewinders, the quality and pro-level construction are immediately apparent as soon as you pick them up. The thick cast shoe, guards, and housing, the oversize bevel, and depth locking levers, the oversize spindle lock button, the clear “can’t miss them” bevel and depth indices…and so on. These saws are confidence-inspiring just to pick up.

Just remember that the blade and threads are reversed on the blade-left saw!

How Do They Feel In Use?

For all their substantial feel, this SKILSAW blade-right and blade-left sidewinders actually don’t weigh a lot, and that’s apparent when you use them. They are just as agile, comfortable, and easy to maneuver as lightweight consumer-grade saw. In the (staged) photo below, the blade-right saw was very comfortable to use in that out-of-position cutting situation.

As befits their pro target market, this SKILSAW blade-right and blade-left sidewinders don’t have a safety or trigger lock-out. That makes them easier to use than consumer-grade saws, and I find it a welcome feature. The lock-out on most consumer-grade saws requires a bit of a learning curve, which admittedly is not difficult, but is kind of a nuisance. As with firearms, the cardinal rule is to keep your finger off the trigger until you want to activate the device.

The cut-line indicators (for 0- and 45-degrees) are bold and high contrast with the magnesium shoe, making them very easy to see and use. And they are clearly marked on both the front AND back of the shoe! Precise bevel and cut-depth adjustments are a cinch.

Does It Do What I Want It To Do?

How does it cut? Keeping in mind these saws’ primary application of framing I tried them both out on 7/16-inch OSB, 2X KD, and 4X4 PT, using only the factory-supplied 24-tooth blade. Both saws cut through one layer of the OSB like warm butter. They cut through two layers of the OSB as fast as I could push them (which is way faster than is safe). On the 2X stock, they cut as fast as I could hold a line.

There was no vagueness to the saw, no chattering, and nothing to suggest that it wasn’t fully committed to the cut

Making full-depth cuts on the 4X4 PT they also cut as fast as I could hold a line…but I had thought they might do better. Then I realized that this piece was probably green, and definitely frozen (it’s winter here in New England). So I pulled out a consumer-grade saw that I’ve used with satisfaction around the house, and indeed it could cut the 4X4 only 1/3 as fast as the SKILSAW blade-right and blade-left sidewinders. So it was the lumber itself that was the difficulty.

The oversize bevel and depth levers were a welcome change from the smaller levers on other saws, and the 45-degree hard stop on the bevel adjustment (with a spring release) was welcomely idiot-proof.

And what about the difference between the blade-right saw (which I’m used to) and its blade-left cousin? No real surprises: depending on your hand and body position one is easier to use than the other. This subject is explored in detail in a companion article here.

Improvements?

For all the oversize controls and super easy-to-read indices, I was surprised that the handle didn’t accommodate gloves very well (and I have average size hands).

There are no accessories supplied with either saw, such as a rip guide or dust port hose adaptor. (Indeed the blade-left saw doesn’t even have a dust chute.) This is more a reflection of their primary use in framing than of any oversight on SKILSAW’s part, and it’s not really something that I see any need to “improve”.

I’ve never seen a sidewinder with a rafter hook, and these saws are no exception. But if SKILSAW could crack that nut it would be awesome, as well as appealing to their pro-market consisting of large numbers of framers.

On the other hand, there’s also no supplied case (either hard or soft). This is something I would like to see. I understand completely that a good hard case would add a fair bit to the saw’s price, but I’d like to see it as an option. No one likes to see their tools just banging around in the truck without some sort of protection. When I was coming up all power tools come with nice metal cases, and I miss them.

Final Thoughts

One thing I can’t tell you is how long this SKILSAW blade-right and blade-left sidewinders will last – I’d have to keep them for many years — at least — to know that! But I’ve got a week’s pay that says that SKILSAW wouldn’t risk their reputation by putting their name on substandard saws that they offer as pro-grade.

If you’re a Type 3 or 4 carpenter, these saws (or their cousins) should be on your shortlist for sidewinders. If you’re a Type 2 and you find joy in fine tools, then you’ll love them.