Installing Schluter DITRA-HEAT-DUO Over Concrete Floors

Solving A Cold Basement Floor With Electric Radiant Heat

We were recently asked to install electric radiant warming in a basement bathroom, concrete floor. The problem with concrete floors is that the cold concrete absorbs heat energy, significantly increasing the time it takes for the tile floor to warm up. In some cases, floors may never reach the desired temperature.

This is even more an issue when there is no insulation layer below the concrete, which was our case. While I have installed floor heat in many spaces, the thought of installing an electric system radiant heat on cold concrete subfloor seemed like a waste.

Adding Heat To A Cold Basement

This particular bathroom had no heat source and no way to add it from the existing system, so an electric floor warming system not only made sense it was the most logical solution to improve the space.

Installing Radiant Heat with A Thermal Break

So how did I decide on Schluter DITRA-HEAT-DUO. I learned that Schluter makes an uncoupling membrane that provides a thermal break [cold break] from the concrete substrate. The product is called Schluter®-DITRA-HEAT-DUO.

Schluter-DITRA-HEAT-DUO is an uncoupling and waterproofing membrane with an integrated bonding fleece that can also be used to reduce sound transmission between floor –ceiling assemblies. The best part is that it solved my issue of heat loss through the cold concrete floor. The DITRA-HEAT-DUO has fleece liner that results in a 70% faster floor warming response time.

Schluter DITRA-HEAT-DUO Benefits

The Schluter-DITRA-HEAT-DUO membrane is 5/16″ (8 mm)-thick, [compared to DITRA-HEAT at 1/4″ (5.5 mm)-thick]and has 4 Benefits:

- Sound Control

- Floor Warming

- Decoupling

- Vapor management

Installing Schluter-DITRA-HEAT-DUO

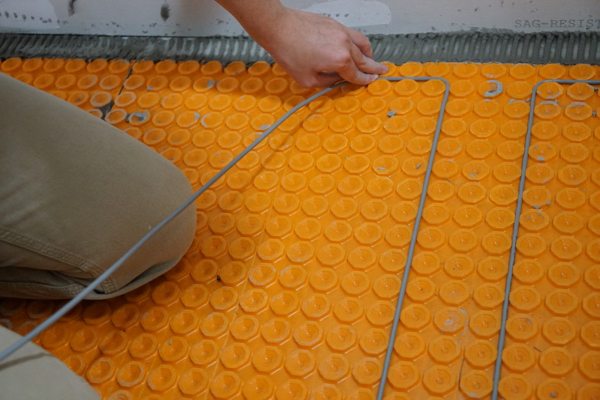

The Schluter DITRA-HEAT-DUO comes in both a roll or by the sheet and has a stud designed to allow for the easy installation of DITRA-HEAT-E-HK heating cables. We chose the sheets since it was a small room, and it was also easier to cut them at the toilet and floor drains.

Planning

When planning your system, use a dedicated round fault circuit interrupter (GFCI). The DITRA-HEAT thermostats have built-in GFCI protection.

Ensure to keep a minimum spacing from the following:

- Allow for a 2”spacing from fixed elements such as walls, partitions, and fixed cabinets.

- Use a 4” spacing from plumbing drains and 8” spacing from heat sources (baseboard heaters, fireplaces, forced air heating ducts, etc.) Lastly use a 7” spacing from centerline of the toilet.

Avoid Placing Heating Cables Under Fixed Objects

NEVER install the heating cable under vanities, bathtub platforms, free standing bathtubs, kitchen cabinets and islands or any other fixtures or in closets. Excessive heat will build up in these confined spaces and may cause cable overheating.

The minimum installed bending radius of the heating cable is 0.5 inches

Preparation For Schluter DITRA-HEAT-DUO Installation

- Wipe down and clean the concrete floor substrate.

- Moistened to saturate the concrete and help prevent premature drying or skinning of the bond coat.

- Dry fit your parts on the floor.

- Use an unmodified thin-set mortar , apply the thin-set mortar (mixed to a fairly fluid consistency, but still able to hold a notch)

- Trowel thinnest with a 1/4″ x 1/4″ square-notched trowel.

- Install and embed the matting into the mortar using a float.

- Lift up a corner of the matting to check coverage. Proper installation results in full contact between the fleece webbing and the thin-set mortar..

- Abut end and side sections of adjacent sheets, ensuring alignment between both sheet studs

- Heating cables may not touch, cross over, or overlap one another.

- Use a dedicated wire chase for the cold lead and sensor wires. [see photo below]

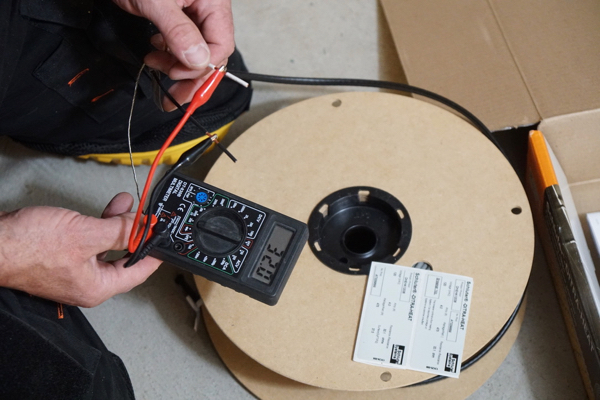

Test Heating Cable

Heating cable testing is required while the heating cable is on the spool and twice during installation.

- Test 1: Conductor Resistance

- Test 2: Continuity between Conductor and Ground Braid +

- Test 3: Insulation Resistance

- Test 4: Thermostat Floor Temperature Sensor

Floor Heat On A Concrete Floor

Now when the electric heat kicks on the tile floor warms fast and concrete subfloor absorbs LESS heat energy.

PRO Tip: Because this bathroom is in an unheated basement we added a door-closer mechanism to the door to keep the door closed, at all times, for heat conservation and to prevent the thermostat from activating more than needed.