Wedi Waterproof Shower System

WEDI Shower System

What we really wanted, and what our clients really needed, was a system that offered 100% waterproofing, minimized mold issues, saved time-consuming steps, and was easy to assemble at the job site. Here’s where WEDI fits in.

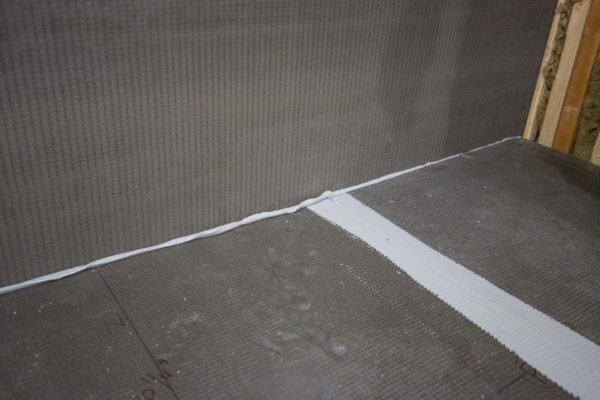

The WEDI Building Panel is a waterproof tile underlayment for walls and floors, manufactured in Emsdetten, Germany. It consists of an extruded, polystyrene core and is covered in a fiberglass mesh and polymer modified cement resin coating.

The core of the polystyrene panel is extruded under enormous pressure to create a dense mass of tiny, closed cells so tightly packed together that water cannot penetrate. Both sides of the panel have an outer covering with a glass mesh coated with a polymer-modified cement coating. The mesh and cement give the panel enormous strength.

The WEDI product is 100% waterproof, will not decay, and is easy to cut to any size with a utility knife. It is not necessary to use cement board /green board/drywall behind the WEDI panels.

We immediately noticed the speed that WEDI can be transported, cut, and installed. It’s much faster than conventional methods and saves money when compared to the many different tasks involved in waterproofing a shower.

WEDI Panel Sizes

The WEDI Building Panel is available in

- 2’x 4 ‘

- 3’x 5′

- 2’x 8”

- 3’ x 8’

- 4’ x 8’ sheets in various thicknesses

- 1/8″

- 1/4″

- 1/2″

- 5/8”

- 1″

- 1 1/2″

- 2″

Fastening WEDI Panels

WEDI panels come as thin as ½” thick and are fastened every 12 inches directly to wood or metal studs that are spaced 16-inches on center. Special washers are used with the fasteners.

1″ WEDI board can be applied directly to studs spaced 19” o.c. framework.

Cost

In comparing square foot pricing, the WEDI Building Panel is more expensive than cement backerboards and fiber-cement boards. However, in comparing value, WEDI Building Panel saves extensive labor, provides a waterproof substrate, is less likely to create an environment for mold, is a crack suppressor, and weighs 75% less than the other products mentioned.

Total job costs are reduced when using WEDI Building Panel when you consider the following other methods:

- Cost, weight and hassle of cutting cement board

- Cost of a traditional method includes a pre slope, shower pan liner, and mortar bed

- Cost of a plumber-installed drain and poly liner

- Time and cost of taping and thinsetting seams

- Cost of purchasing and applying waterproofing sealer

- Cost of waterproof membrane

Part of the cost savings that is not immediately realized by contractors is the speed with which a WEDI shower system can be installed. It took us one day to install this one versus the several days it would have taken using traditional methods.

The WEDI shower system installs faster and easier because it is lightweight, cuts with a utility knife, and needs only 1 fastener per square foot. The end result is a fully waterproof surface.