Milwaukee FUEL 18 Gauge Brad Nailer 2740-21CT

Concord Carpenter Tool Test

We took the Milwaukee FUEL 18 Gauge Brad Nailer 2740-21CT into our shop for some preliminary testing and to verify if Milwaukee’s claim of 1200 nails on one 2.0 Ah battery pack was accurate.

It’s worth noting, that Milwaukee runs these nailers though dozens of life testing and hundreds of thousands of brads, in all types of materials, before they release it to the market. They wanted to make sure that the nailer is capable of reliably installing 100,000 nails before maintenance may be needed.

They also engaged in a ton of field research on how these tools are used on a job-site and developed real-life usage cycles to test the tools to reach a level of tool performance that pro contractors would expect in a cordless nailer.

One test Milwaukee uses is to fire one fastener every 4-seconds. They arrived at this test since it mimics how a contractor might use a brad nailer.

Concord Carpenter Run-time Testing Criteria

For our runtime test we decided on a slightly different approach. We chose to use 2-inch brads with the brad nailer set on single sequential operation. We prefer using our finish nailers in this setting for safety and it is most realistic setting when you’re trying to install fasteners accurately.

We constructed a fastening board consisting of ¾” Poplar, ½” blue board and a 2×6 Spruce framing member all fastened together. Choosing this material, since it best represented fastening trim material onto a residential wall.

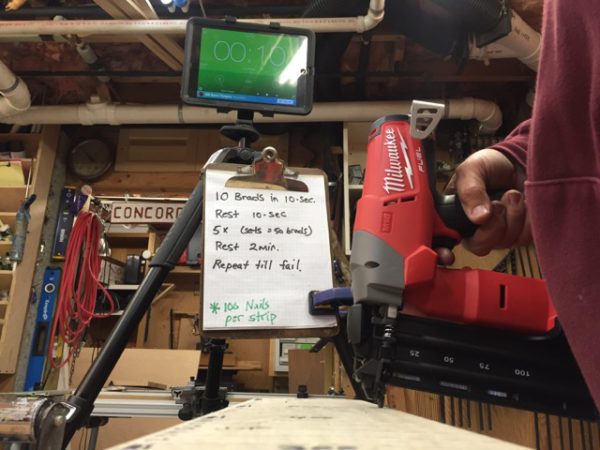

Using an iPad with an exercise circuit trainer timer, we proceeded to install 10 brads in10-seconds, resting the tool for 10 seconds for 5 sets, and then letting the tool rest for 2 minutes before repeating. [see below]

Testing Rate of Fire

- Install 10 brads in 10-seconds

- Rest tools 10-seconds

- Repeat 5x [50 brads]

- Rest 2-minute [after every 50 brads]

- Repeat until battery drained and unable to fire

- If tool experienced thermal overloaded protection, we allowed a 2 minute rest, and then continued

Fastening Rate

Our fastening rate was based off of trying to balance time and effort, while placing the tool under an aggressive and stressful fastening condition. We wanted to avoid bump firing the nailer for safety, accuracy and it would be too easy to abuse the tool forcing a thermal shutdown.

Unless you’re a trim carpenter getting “paid by the lineal foot,” you don’t need to use bump firing on finish nailers. Punishing this nailer with a continuous bumping nailing rate would be been realistic and unprofessional.

In fact, if you stop to think about how you use a brad nailer it might look something like this:

- Install 5 to 10 brads in one time

- Measure

- Walk to your miter saw to make a cut or cope molding, or wait for a cut man to do this for you

- 1-2 minutes later to install more brads

Its important to note that there is no way that you would use your brad nailer as aggressively as we tested it.

The goal was NOT to put the tool into thermal overload and to be semi- realistic in our fastening, but as I mentioned earlier, this was an aggressive test and we DID put the tool into thermal protection mode, several times. In these situations we placed the tool down, powered on, battery in, for 2-3 minutes and then resumed testing.