Kreg Universal Workbench

Workbench Solutions | Kreg Work Bench

I have a small shop! There I said it. When you’re trying to get work done in a small shop you have to be able to do more with less, be comfortable working in a cramped space, and be creative. Creativity usually means choosing multiple-use tools and, benches and putting everything on wheels. So, this brings me back to the phrase small shop workbench solutions. In this article, we use the Kreg Universal Workbench to solve some of our small shop problems.

Small Workshop Bench Solutions

For years my table saw outfeed table doubled as my workbench assembly table. The main reason for this is a lack of space, but also my outfeed area sits in the central area of my shop. Over time I’ve added amenities such as overhead power, dust collection, clamp storage, and compressed air. This setup worked great until it didn’t. It doesn’t work when you are knee-deep into a project on your assembly table and realize that you need to rip something on the table saw, that’s when the trouble starts.

The Paulk Workbench

Through the years, I’ve gone through many iterations of shop workbench’s and am always on the look for that unicorn small shop workbench solution. Currently, I’m using the Paulk workbench, which has been great, but not a total solution, for me. Once a heavy project is built on the Paulk bench my table saw becomes useless for anything other than small rips.

The Paulk table is the right size for my shop but for it to work well, I’d need to be able to split it in two and put it on casters. That got me looking at the KREG Universal workbench.

KREG Universal Workbench

The Kreg Universal Workbench is a system of rails and adjustable height legs that are available in multiple sizes. By combining two different-sized legs and five different-sized rails, you can create a customized workbench with a lower shelf, a tool stand, an outfeed table, or an assembly stand. The KREG bench comes in 15 possible sizes from 14″ x 14″ up 64″ x 64″ – with two different, adjustable heights.

- 31 to 39” height

- 17-1/4″ to 23-1/4″ height

The Kreg bench can also accept 3-inch casters, with ½” threads, dual-locking, swivel movement mechanism. Each caster has a load-bearing rating of 150 pounds. The 600lbs capacity appealed to me.

Kreg Universal Bench with Standard-Height Legs | 28″ x 64″

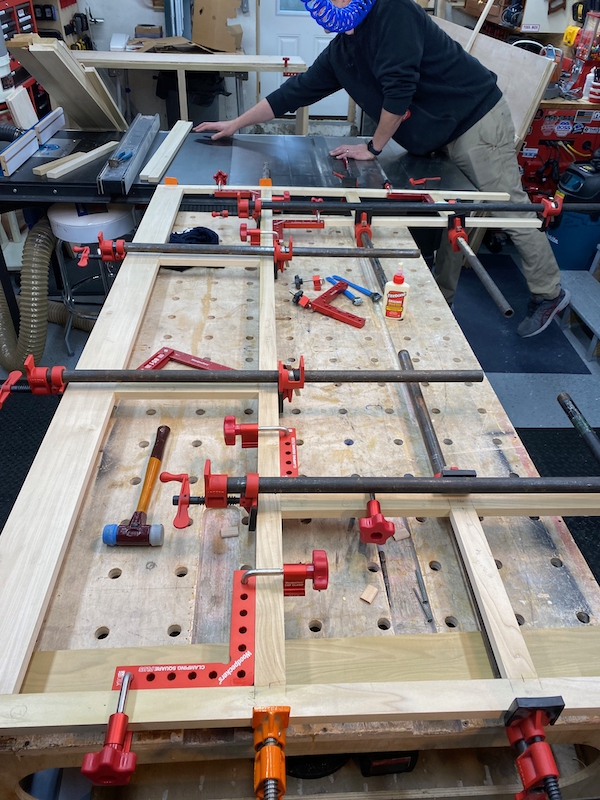

I locked my sights on the 28” x 64” Kreg Universal Workbench and decided that I would build two tables, both on casters. This would allow me several workbench configurations:

- Bolt or clamp the two together for one large assembly table

- Split the two, keeping one as the outfeed and the other as a narrower assembly table.

- Roll one or both around the shop as needed

Table Saw Outfeed Table and Tabletop

With a 1-inch overhang a 28″-wide by 64″ Kreg Universal Workbench measures 30” x 66”.

My table saw is 35-1/4” high which meant I could use the adjustable standard leg kit to achieve my heights with two layers of ¾” plywood for my top. The leg levers have a 6-inch adjustment range. Having both tables at the outfeed height is crucial for me when cutting long material, or sheet stock. In the end, my KREG table came to 35 1/8” – acceptable for me.

I also added the Kreg Clamp Trak to two sides of the sub-table and then filled in the tabletop with Melamine. This flush mounting keeps the Clamp Trak below the surface of my outfeed top. The Clamp Trak allows me to use the Kreg Bench Clamp of any t-track accessory to clamp materials along two edges of my table.

Outfeed Tabletop | Materials Used

Some woodworkers expect their workbench top to get messy and don’t care. And they choose cheaper material for the top or plan to change it out regularly. For my outfeed table, I chose to use ¾” black melamine [laminate] for its impact resistance, low maintenance, and the black laminate matches my Delta Unisaw black outfeed table.

The melamine comes in a ¾ x 4’ x 8’ sheet and is durable and smooth. As an outfeed table sliding across this sheet is effortless. As an assembly table, the surface is smooth and easy to wipe glue off and is wear, scratch, scuff, and mar resistant. I installed this top with screws from the bottom side facing up.

The tabletop is a total of 1-1/2”, the top is Melamine with a sublayer of ¾” AC plywood. For the tabletop edges, I overhang the table 1” and attached Poplar wood, edge banding. I used a ¼” round over bit to smooth the Poplar edge banding. For the bottom shelf, I used ¾” AC plywood

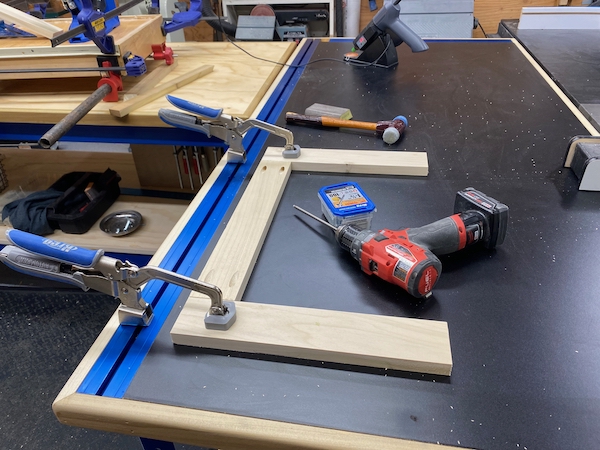

Assembly Table

For the assembly table, I used two layers of ¾” AC plywood. I choose plywood for this table because I want the ability to be able to install screws or other fasteners as needed into, the top. [Melamine would not be a good choice for this.] Additionally, I can sand this top to clean it or replace it by removing 10-12 countersunk screws.

For the tabletop edges, I overhang the table 1” and finished it off with 1-1/2” Poplar wood, edge banding. I used a ¼” round-over bit to smooth the Poplar banding.

Note- The Poplar banding was glued and fastened to the bottom layer only. This will facilitate the replacement of the top layer if needed.

Tool Storage | Bottom Shelf

The KREG table allows for a second lower shelf with some adjustability. I kept lowering mine as low as I could get it, and still get a broom or vac under it.

For both tables, I used ¾” AC plywood and some simple Poplar edging. I coated all the AC plywood shelves with a sanding sealer

Under the assembly table, bottom shelf, I added some cross braces to allow me to slide two pieces of rigid foam underneath. I use the foam under stock when cutting with my track saw. On one end of the bench, I added, an extension shield for my Festool CT Mini vacuum. This vacuum is a dedicated sanding vacuum and I used to have to wheel it out from across the room and hook up a sander to it. With my extension shelf, I will keep the sander attached to the vacuum at the end of my bench, ready to go.

I used some left-over AC plywood to build a box and upper shelf for my often-used tools such as tape measure, utility knife, pencils, square, and hand plane.

Kreg Universal Workbench Accessories

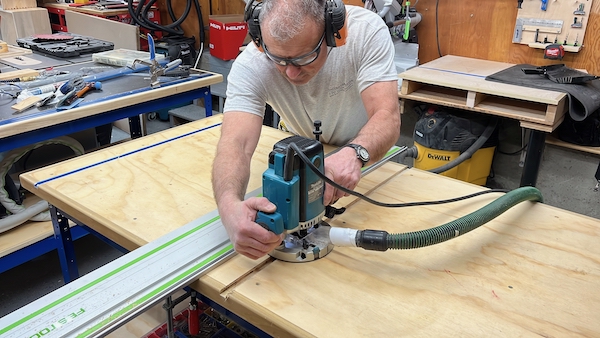

On my assembly table, I added three Rockler T-tracks for clamping. I routed three grooves, approx. 5 inches in from the edge, on both sides, and one in the center of the table, for the t-tracks. This will allow me to use inline clamps, like the Kreg Clamp, and Rockler Auto-Lock Hold Down Clamp.

Additionally, some Rockler accessories, are designed to work with the T-track system. I’m going to try out on my next assembly and glue-up, they are:

- Rockler Auto-Lock Hold Down Clamp

- Rockler Inline Cam Clamp

- Rockler Shortstop

- Rockler 90-degree corner stop

On the outfeed table, I added the Kreg Clamp Trak system to one long and one short edge. The Clamp Trak is an anodized aluminum track that is approximately 2-1/4″ wide, 3/4″ thick, that can be routed to recess in benchtop or stagger between two 3/4″ thick panels, as I did. Numerous ¼” bolts secure it to the track to the plywood sub table.

The Clamp Trak will allow me to use Kreg Bench Clamps and Automaxx Bench Clamps along the entire length of the workbench as a clamping station. I installed the Clamp Trak to the AC plywood sub-base and then installed the Melamine next to it.

Kreg Universal Workbench | Conclusion

The Kreg Universal Workbench has a slew of modular options. It can be modified to create a workbench, assembly table, tool stand, or outfeed table in a custom size to fit your space, your projects, and your needs. I like the different options and configurations.

It certainly helps me solve my problem of having to use my outfeed table as an assembly table. Now I have two smaller tables, both on casters, that allow me to move the position of the tables, and use my assembly table without interfering with the table saw outfeed operations.