Fiberglass Vs Closed Cell Spray Foam Insulation

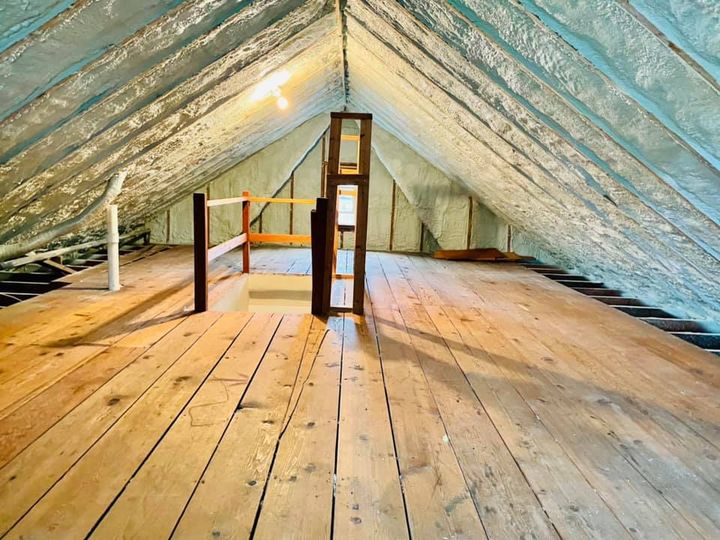

APEX Insulation Inc., blowing foam insulation

Fiberglass Vs Closed Cell Spray Foam – Best Insulation?

The debate always surrounds fiberglass vs closed cell spray foam insulation. There are many different types of thermal insulation and the performance characteristics of these materials vary greatly as well. The most common types of insulation used in modern building practices consist of:

- Fiberglass batts

- Mineral wool batts

- Blown-in cellulose

- Preformed foam polystyrene

- Polyurethane or polyisocyanurate boards

- Polyurethane spray foam insulation. [Open and Closed Cell]

As a contractor, I often get asked why do I use closed cell spray foam on my products, and what are the benefits when compared to traditional fiberglass insulation. I recently had a chat with Brandon Maranian from Apex insulation to discuss this and see if I was on the right track on my projects.

In a nutshell, I prefer using closed-cell when the budget allows. When talking to clients I use this breakdown to explain insulation effectiveness:

- Closed-cell spray foam R6.5 per inch

- Open-cell spray foam R3.5 per inch

- Fiberglass insulation R 2.2 per inch

Brandon broke the two spray types of foam insulations down for me and then compared them to fiberglass insulation.

What is Open Cell and Closed Cell Insulation

Not all spray foams are created equal. Both open-cell and closed-cell spray foams result from a chemical process by mixing isocyanate and polyol at the site of application that rapidly expands between 30-100 times its size. Spray foam is applied by a high-pressure applicator gun directly to the area being insulated. The foam rapidly cures and adheres in place.

Open-cell spray foam has a higher expansion ratio of 100:1 than closed-cell and is a great thermal and sound insulator. Open-cell foam has an R-value of roughly 3.5 per inch. The cell structure of the foam isn’t completely closed and as a result, the foam is a bit softer and more flexible. With adequate depth, open-cell can act as a good air barrier but it cannot act as a vapor barrier.

Closed-cell spray foam [CCSPF] has a lower expansion ratio of about 30:1 and results in a foam that is denser and more rigid than open cell insulation. The closed-cell foam has a cell structure that is completely closed. This closed-cell nature allows CCSPF to act as a vapor barrier in addition to having a fantastic R-value of 6.5 per inch.

Fiberglass Vs Closed Cell Spray Foam

Some reasons why closed cell spray foam [CCSF] is far superior compared to traditional fiberglass & cellulose products when insulating the exterior shell:

Fiberglass allows air & moisture to pass through it easily – CCSF is superior because it is in itself an impermeable air & moisture (vapor) barrier.

Fiberglass R-value has depth limitations based on the existing framing – CCSF boasts the highest R per inch of any insulation on the market. Closed-cell spray foam has an R-value of roughly 6.5 per inch while open-cell spray foam has an R-value of 3.5 per inch. The R-value of fiberglass is significantly lower at around 2.2 per inch. In addition, fiberglass insulation loses R-value over time while spray foam insulation maintains its effectiveness.

Once the temperature outside falls below freezing, around 20º F or below, fiberglass loses as much as 50%of its R-value. Spray foam will lose some of its R-value but very little compared to fiber products. Closed-cell spray foam is also not affected by temperature and moisture like fiber products.

Fiberglass requires the use of traditional roof and baffle venting to flush out any moisture that travels through the material. In turn, this intensifies the structure’s stack pressure, increasing the flow of air. This hinders efficiency through the loss of conditioned air and also negatively impacts comfort by increasing air infiltration/draftiness. Air that is lost, is replaced by an equal amount from outside. CCSF eliminates the need for ventilation in most cases, reduces the structure’s stack pressure, and retains conditioned air temperature for a long period of time due to its impermeability. This is ideal for those seeking superior comfort & savings.

Fiberglass provides NO structural benefit. CCSF is rigid in its cured state and increases the roof’s structural strength significantly. This is important for those seeking to stormproof their residence.

Fiberglass breaks down over time as air & moisture pass through it. This can release tiny particulates into the living space air leading to poor, polluted indoor air quality. CCSF once cured is inert and does not break down over time when shielded from UV light.

Fiberglass can be a breeding ground for rodents, insects, and mold. It is quite usable for nesting. CCSF is a moisture inhibitor and is too rigid to be used by rodents. In most cases, it cannot be bored into/through by rodents or insects.

Closed Cell Spray Foam Limitations

Closed-Cell spray foam is a great air and vapor barrier but it is not effective at sealing liquid water leaks. If the basement in question has a problem with external liquid water migration, this issue can not be solved with spray foam. The sources and causes of the water need to be corrected before the spray foam is installed.

Insulating Roofs and Attics

Insulating Roofs and Attics

For rooflines, there are two acceptable options when insulating using spray foam products:

- All closed-cell – 6.5″ = R49

- Hybrid – recommend a 3″ closed cell base layer and 7″ of open-cell foam

The hybrid model is best used when there is HVAC existing beneath the spray foam ie. an unfinished attic. The increased material depth is typically enough to bury the roof rafters, creating a thermal bridge and eliminating roof exterior striping (where heat transfers through the rafters and melts rooftop snow).

Insulation Rim Joists

One of the best uses for closed-cell spray foam is to seal and insulate the exposed rim joist areas. The irregular shape of a rim joist and foundation can be a difficult area to insulate with other methods.

Conclusion

After discussing this over with Brandon I still feel that closed cell spray foam when installed properly by a trained professional, can be the best insulator as well and perform admirably against high moisture, mold growth, and heat loss.

Photo Credit: APEX Insulation