Basement Moisture and Insulation

BASEMENT MOISTURE STRIKES AGAIN!

By Kaethe Schuster, Retrofit Market Manager, Dow Building Solutions

A house with water problems does not necessarily mean it was poorly constructed as moisture can appear in well-built homes. One thing that all homes have in common is direct contact between the foundation and the earth, which can have costly consequences not only to the structural integrity of the home, but to the indoor comfort and health of its occupants as well. Builders understand the need to protect below-grade walls and foundations from potential moisture damage, but proper exterior continuous foam insulation systems can also significantly reduce heat loss through concrete walls, resist odor-causing moisture, keep crawl spaces dry, and protect against frost. This is value and performance that homeowners relate to and understand.

Luckily, there are several ways either a contractor or a DIYer can upgrade an existing basement to help combat some of these issues.

Basement Moisture and Insulation

THE CHALLENGES:

Basement walls and foundations must be able to withstand considerable pressure from both soil and water. The weight of soil exerts significant vertical pressure and as the weight of the soil presses downward, it also exerts horizontal (or lateral) pressure against the basement wall. An insulation material with sufficient compressive strength is needed to resist this constant pressure without losing its R-value or drainage capability.

Foundation walls need to withstand a consistently wet environment caused by rain, melting snow and the local water table. The concrete and cement block typically used to build foundation walls in North America absorb water from the soil and allow it to move through the walls. Water can also pass directly through cracks in basement walls. In these harsh underground conditions, exterior insulation must retain its R-value when wet, protect the waterproofing membrane from backfill damage, keep the foundation walls warm and resist water absorption and compression from soil loads.

Hydrostatic water can also be constant against basement walls and foundations, and the pressure increases with depth. Water will pool at the lowest point on a wall without proper drainage, and as pressure builds, the water will penetrate even the smallest cracks in the foundation. Insulation with drainage grooves that direct water down to the drainage tile – away from the foundation – is the best remedy.

THE SOLUTIONS:

To address basement moisture issues, it is important for builders and contractors to regard each home as an overall system to be insulated and sealed, including below-grade walls and foundations. Homebuilders and remodeling professionals can offer their customers enhanced energy efficiency, moisture protection and hydrostatic pressure resistance that will help keep their basements dry, comfortable, and free of odors caused by damp conditions, while providing a valuable energy savings improvement.

There are a variety options and solutions for basement insulation needs that are designed specifically for use on exterior basement walls, interior crawl space walls, and interior basement walls. At Dow, we recommend using a combination of air sealing and rigid foam insulation for basements and we offer a variety of products for both professionals and DIYers.

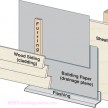

Exterior Basement Wall

In addition to energy loss that leads to higher energy bills, uninsulated exterior walls can result in condensation on cool basement wall surfaces. If you’re able to excavate the basement exterior during a retrofit, it’s a good idea to insulate the exterior foundation to save energy, keep basement walls warm, and reduce the potential for moisture problems that can lead to mold and mildew. Installing a continuous layer of rigid insulation products like STYROFOAM™ Brand PERIMATE™ Insulation provides your wall with long-term thermal performance, exceptional moisture resistance, and added compressive strength to resist soil and hydrostatic pressures. This is achieved through specially designed dovetail grooves that face the soil to channel water down to the footing drains of weeping tiles.

Interior Basement Wall

Dow has multiple insulation solutions that are easy to install on the interior of basement walls, whether finished or unfinished. For basement wall insulation, the do-it-yourselfer may prefer to install THERMAX™ Insulation or hire a professional to install STYROFOAM™ Brand Extruded Polystyrene Foam. For an unfinished basement, THERMAX™ Sheathing and White Finish Insulation products are among the most energy-efficient insulations available today, with an R-value of 6.5 at one inch thick. Easy, quick and clean to install, THERMAX may be left exposed in living areas like basements. THERMAX White Finish Insulation features an embossed white acrylic-coated aluminum facer on its exposed surface for a clean, finished wall appearance that is both durable and washable. For a finished basement, a professional can install rigid foam insulation such as STYROFOAM™ WALLMATE™ over framing and then cover it with drywall; this allows spacing for electrical wiring and other service penetrations and creates a finished appearance.

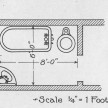

Rim Joist

No basement insulation project is complete without making the rim joist area energy efficient. Even if the basement is not intended as an additional living space, seal and insulate rim joists for immediate energy savings and blocking the entry of unwanted airflow, dust, moisture, spiders, ants and other pests. The rim joist is a significant source of air infiltration and potential energy loss in the home. There are two ways to air seal and insulate this area. The preferred method is for a professional contractor to apply FROTH-PAK™ Foam Insulation, a Class A foam that comes in an easy-to-use portable kit. A quick and easy alternative to using FROTH-PAK™ Foam Insulation that professionals can do is to install a piece of rigid insulation board in the space and “picture frame” around it using GREAT STUFF PRO™ Gaps & Cracks Insulating Foam Sealant. Just cut a piece of insulation board to fit, then seal around the perimeter to secure it in place and block air infiltration around the edges.

Crawl Space

The practice of adding vents to crawl space walls can allow moisture vapor to enter the crawl space where it may condense on cool floor joists, batt insulation, HVAC equipment and plumbing fixtures. Wet surfaces or high humidity in the crawl space can support mold and mildew, distort wood flooring and affect indoor air quality. A good alternative to vented crawl spaces is unvented, well insulated spaces. Rigid foam insulation on the interior of crawl space walls in an essential component of unvented crawl space systems which help keep crawl spaces dry and energy efficient.

Protect your basement from moisture and its related issues. With simple insulation and air-sealing solutions your basement can be dry and comfortable for you or your customer to enjoy!