CHANNELLOCK® Electrician’s Pliers

CHANNELLOCK has Electricians Covered

CHANNELLOCK electrician pliers is kind of a tautology. That’s because CHANNELLOCK makes many versions of all the pliers that electricians commonly use, including the four pliers that are in almost all electricians’ tool pouches all the time. These are lineman’s, dykes, tongue-and-groove offset head (known generally as “Channelocks”, because CHANNELLOCK invented them in 1933), and needle nose. While all four of these plier types are used in many, if not all, trades, it is lineman’s that are most commonly thought of as electrician’s pliers.

As soon as I was old enough to wear a hand-me-down electrician’s tool pouch, I was carrying and using CHANNELLOCK tongue-and-groove offset head pliers (AKA “Channellocks”), as I described here in a review of some new versions of them. Here we look at two other tools that CHANNELLOCK makes for electricians.

Lineman’s vs. Combination Pliers

Not only does CHANNELLOCK make lineman’s pliers that are always mentioned in the top tier of lineman’s, but they also make European-style “combination” pliers that are favored by electricians in Europe. To refresh you, the picture below shows the two types side by side in profile. Lineman’s are generally larger – both thicker and generally about an inch longer. They have a larger set of jaws and a longer set of cutting knives. They often incorporate features such as a crimper or fish tape puller. Combination pliers have slightly smaller jaws and a shorter set of knives, but incorporate an oval-shaped hole with teeth for grabbing onto and turning round-ish things like bolt heads, small-diameter conduit, and so on. Combination pliers usually don’t incorporate other features.

(Both types of pliers are actually “combination” pliers in that they combine, at least, a gripping and a cutting function. But in the industry, “combination” pliers usually refers specifically to the type described above.)

I got to thinking about why lineman’s are almost universally favored by American electricians, while combination pliers are the favorite in Europe and Australia. I’ve found myself using smaller pliers for electrical work on more than one occasion, and I read that some American electricians have switched over to combination pliers from lineman’s. Of course, it all depends on the kind of work you’re doing, but I wanted to compare the two types side-by-side. I reached out to CHANNELLOCK to ask if they’d provide a sample of each, and they generously agreed. They also sent along a version of their lineman’s that I hadn’t used, one that’s sort of midway between traditional lineman’s and combination pliers…and I think I may have found the Holy Grail of electrician’s pliers!

CHANNELLOCK: A Rare Bird

CHANNELLOCK was founded in 1886, and today is run by the 5th generation offspring of the founder. It manufactures over 75 types of pliers in Pennsylvania. It is a rare company in four ways. 1) It manufactures what are everywhere regarded as high-quality tools. 2) It does so in the United States. 3) It is run by the same family that founded it. 4) With all the foregoing, it is a profitable, going concern. Now, 3) is very unusual. 3) and 4) together are almost unheard of. Throw in 1) and 2) and you have a very rare company indeed.

What’s That Gap?

On both lineman’s pliers and combination pliers there’s a slight gap in the jaws when the pliers are fully closed. Many people who are new to these tools think that the gap must be a defect in the pair that they got. Even professional users of them sometimes just figure, “Well, that’s the way it’s always been”, without fully realizing why the gap exists.

That gap is there on purpose! There are many fanciful “explanations” on the web as to its purpose, by people who’ve clearly never used these pliers for actual work. But the real reason is the reason that the manufacturers themselves explain: it’s there to allow the cutters to continue to cut effectively as they wear. If the jaws fully closed, then as the cutters wore (and of course they will) the jaws would prevent the cutting knives from fully contacting, and they couldn’t cut through material completely.

You aren’t using either of these pliers to pick up tin foil. There’s nothing that you’ll be manipulating with the jaws of this type of pliers that require them to completely close. That gap is a feature, not a defect. In fact, it’s there to be in conformance with the ASME standard (B107.500-2020) that applies to this type of plier.

CHANNELLOCK 369 Lineman’s Pliers

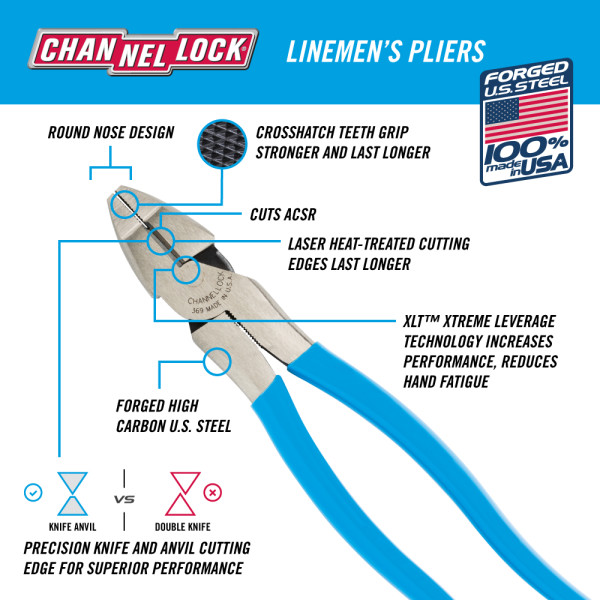

The first of the CHANNELLOCK electrician’s pliers is the model 369 9.5-inch XLT round-nose lineman’s pliers, their flagship lineman’s model. This is the model that’s consistently cited in every list of top-tier lineman’s. It features:

- Xtreme Leverage Technology (that’s the “XLT” in the name), meaning that the pivot pin is very close to the jaws, providing high leverage

- ACSR rated

- Crosshatch jaw teeth

- Laser heat-treated, precision-machined knife and anvil-style cutting edges

- Forged high-carbon U.S. steel, specially coated for ultimate rust prevention

- CHANNELLOCK BLUE® grips

- 100% made in the USA

- Round-nose (New England nose) design

- 08 pounds

- 5-inches long

- 7/16-inch jaw width (approx.)

- Approximately $30 street price

The model 369 is also available with CHANNELLOCK’s CODE BLUE® comfort grips (model 369CB) and with a crimper (model 369CR). The balance point of the standard model is just about midway along its length.

CHANNELLOCK 348 Combination Pliers

The second of the CHANNELLOCK electrician’s pliers is the model 348 8-inch Combination Lineman’s Pliers. These are typical of the combination pliers that are so popular with sparkys overseas. Features:

- Sleek, lightweight, with pipe grip feature

- Xtreme Leverage Technology (XLT™)

- LASER heat-treated cutting edges perform better and last longer

- CROSSHATCH TEETH to provide maximum grip

- Laser heat-treated knife and anvil-style cutting edges

- Forged high-carbon U.S. steel, specially coated for ultimate rust prevention

- CHANNELLOCK BLUE® grips

- 100% made in the USA

- 6 pounds

- 8-inches long

- 5/16-inch jaw width (approx.)

- Approximately $30 street price

Differences in the Pliers

The specs tell a lot of the story: the combination pliers are smaller, lighter, and narrower. The lighter weight of the combination pliers makes them considerably more nimble in the hand. On the other hand, they don’t have the heft you want when pressed into service as a hammer (and all electrician’s pliers are at times). I can definitely see the attraction of the greater nimbleness to the state-side electricians who’ve switched to them.

However, the wider jaw of the traditional lineman’s pliers makes twisting wires together easier. The lineman’s could easily twist four 12 gauge wires; and while the smaller-jawed combination pliers could also, you have to focus on getting everything lined up just right (see photo below).

12 gauge wire, combination pliers

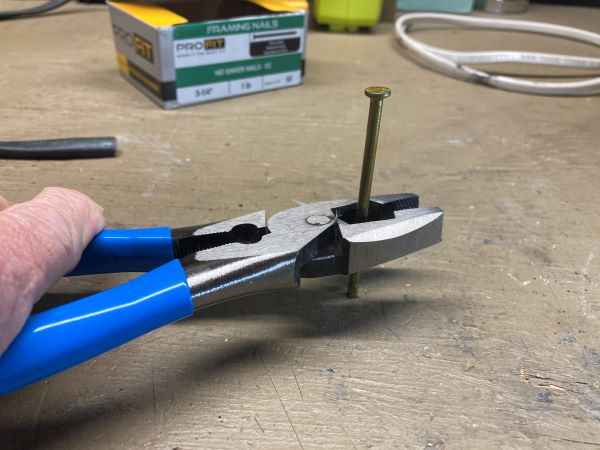

It was no surprise that the larger, longer lineman’s cut romex more easily. While effort is subjective, I found that in cutting thru both 14/2 and 12/2 romex I had to exert about 50% more effort with the smaller combination pliers. While the 369 lineman’s are rated to cut ACSR, ACSR is not something that a lot of electricians run into often (it’s more of an actual lineman’s thing). But we all run into the occasional nail that needs to be cut out of the way. To pick a difficult case, I tried both pliers out on 16d sinkers. The 9.5-inch lineman cut them (using both hands), while I couldn’t get the 348 combination pliers to cut through. (To be fair, I’m not as strong as I used to be, and my hands are a bit arthritic these days.)

I have to say that the toothed oval recess on combination pliers confuses me. Trying to grab a fastener head with them is clumsy and the torque you get is pretty anemic. I suppose that it could be handy for holding and turning things with a cross-sectional diameter of up to 5/8-inch, but I can do that more easily, more effectively, and reach more places with a pair of pump pliers…which of course CHANNELLOCK is famous for and which most of us have with us anyway. Of course, this style of pliers is used in many other trades other than electrical work where the toothed oval may well be quite useful. Obviously, the popularity of combination pliers suggests that I’m missing something here.

Why the Different Preference?

Given the performance differences described above, why are combination pliers the standard electrician’s tool in Europe and Australia, while lineman’s are in the States?

The folks at CHANNELLOCK offer some reasons.

First, Europeans prefer the greater versatility of the lighter combination pliers. Second, Europeans prefer two-component (AKA “comfort”) grips (CHANNELLOCK’s version is called “Code Blue” grips) and CHANNELLOCK mostly offers lineman’s in Europe with dipped grips. Third, electrician’s pliers fall under some heavy regulation in Europe, and many state-side lineman’s manufacturers choose not to invest in expensive regulatory approval in what is, to them, a secondary market. Fourth, the larger, heavier lineman’s are more expensive than combination pliers. Fifth, European countries don’t recognize ASME standards for larger nose plier designs that U.S. lineman’s are made to.

In addition, I suspect two more general reasons.

First, 220 volts is the normal residential voltage in Europe and Australia. The higher voltage there means that smaller gauge wires (and thus smaller-jawed pliers) can be used. At 220 volts a 22 amp circuit requires 2.5 mm^2 diameter wire (about 14 AWG), while a 16 amp circuit is run with 1.5 mm^2 diameter wire (about 16 AWG).

Second, the electrification of the different continents happened more or less independently. Lineman’s pliers were originally developed in the U.S. for telegraph lineman working on 8 AWG wires, and so were already in use by electrical workers by the time that cities started to be electrified. I imagine that the electrification of Europe caused the new trade of electricians to borrow from the pliers that were in use at the time there.

So Which One is Better?

It strikes me that both continents have standard pliers that best meet the demands of the electrical systems they are working on. I suspect (but don’t know) that European electricians working on higher voltages may use U.S.-style lineman’s, or at least larger than 7- or 8-inch combination pliers. Conversely, U.S. electricians can often move to combination pliers like the CHANNELLOCK 348s if they are working in many residential and commercial environments, and gain considerable comfort by so doing. (But I’d keep a pair of lineman’s like the CHANNELLOCK 369s in my bag in case they were the better tool for a situation.)

But…what if there was a plier that combined the best of both kinds?

CHANNELLOCK 368 Lineman’s

Remember that I said CHANNELLOCK had sent along an extra pair of pliers? CHANNELLOCK 368 Lineman’s (model 368), approximately $26 street price) are 8.5-inch lineman’s pliers. They have the same jaw width, are about 1 inch shorter in length, and weigh only slightly less than the standard 9.5-inch 369s (other specs are similar). But they feel much livelier. In the hand they are closer to combination pliers, but in performance they just about match the 9.5-inch model 369 lineman’s. To my hand, CHANNELLOCK’s 8.5-inch 368s have the best of both worlds.

Nine-ish inches is the “standard” length for lineman’s with most electricians, while they are also available in other sizes. Lineman’s in the 8-inch range are used with some frequency in many trades, but I haven’t seen too many of them in the electrical trade over the decades, at least in my neck of the woods. But I definitely advise electricians to try them out!

Bottom line: Whether you prefer the standard-length CHANNELLOCK 369 lineman’s, the 348 combination pliers, or the 8-5-inch model 368, CHANNELLOCK has a pair of lineman’s pliers that will suit you well. And all the other pliers that you’ll need, too!