Workshop Safety

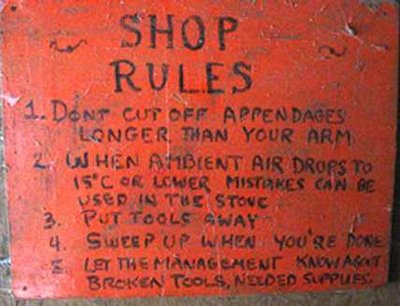

Workshop Safety Rules

Woodworking can be a fun and enjoyable hobby, IF you follow some very basic and simple rules. All workshop safety rules are based on common-sense, but failing to follow these rules will greatly increase the chance of injury when working with your tools. Stay safe!!!

1) Think Before You Cut

The most powerful tool in your shop is your brain, use it. Thinking your cuts through before acting can help save both fingers and prevent excessive scrap wood.

2) Keep a Clean Shop

A cluttered shop is an accident waiting to happen. Keeping your shop clean will help protect you, and your tools, from tripping hazards.

3) Avoid Distractions

Focus on what your doing. Looking up to watch the shop TV can result in your hand contacting the blade. Always wait until you have completed your cut before you take your eyes off the blade.

4) Don’t Rush

Mistakes happen when we rush to complete a job.

5) Don’t Force It

If your saw is resisting the cut, stop and see what’s wrong. A misaligned rip fence or improperly seated throat plate can sometimes cause a board to get stuck in mid cut. Forcing the board in these situations may cause kickback or contact with the blade. Evaluate the situation and solve the problem.

6) Protect Yourself

Eyes, Ear Protection, and Lung Protection should be used when operating tools. Use push sticks and feather blocks when working close to the blade.

7) Let the Tool Stop

Giving the power tool time to wind down after a cut is an often-overlooked safety mistake. Even without power, the spinning blade can still do a lot of damage.

8) Fumes and Dust

Solvent fumes and airborne dust can present health and explosion hazards. Care should be taken to ensure a supply of fresh air.

9) Wear Appropriate Clothing

Loose clothing or hair can get caught in power tools and cause severe injury.

10) No Alcohol

Too many woodworkers have been injured because alcohol clouded their judgment. Avoid their mistakes, practice workshop safety, and wait until after you’re done in the shop for your “Miller Time.”.

Check out our Best Benchtop Thickness Planer article

~ a concord carpenter