Using Sacrificial Foam Board To Break Down Sheet Goods

Breaking Down Plywood With A Track Saw and Sacrificial Foamboard

Ripping full sheets of plywood safely and accurately on the table saw can be a challenging balancing act, especially if you’re alone. Trying to hold a 60 lb. piece of plywood flat on a table saw while pushing it through the saw blade and trying to keep it tight to the fence is not nearly as accurate as you’d think.

There is no argument that circular saw, panel saw or a track saw make this task easier and more effective.

I want to talk about using sacrificial rigid foamboards to support the sheet of plywood while making rips or crosscuts. It’s a safe, effective and accurate method to break down panel goods wither on a bench, sawhorses or the ground.

Set your blade to cut completely through the plywood approximately 1/8 – 1/4 inch and make your cut one pass. The blade will cut into the foam board and not damage anything below it.

The foam board is light and supports plywood fully. (whether on the ground, bench, or saw horses) It protects my workbench surface from saw kerfs and the best part lets me cut through the plywood filly creating a tear-free rip cut.

The foam board costs around $45 a sheet, is reusable and if stored properly should last you a long time.

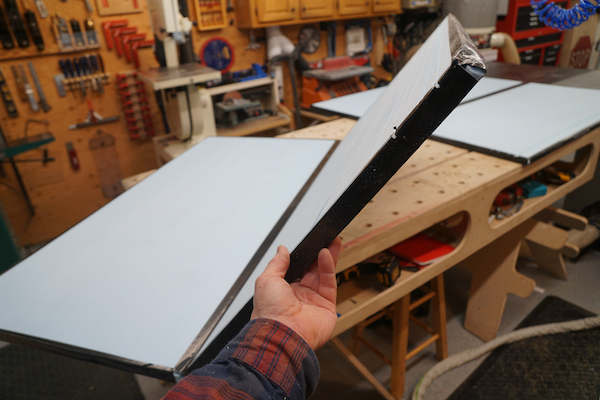

I purchased two 1-1/2” 2×4 foam boards and taped the long, vertical seam together with duct tape to create one 4×8 sheet with a hinge. Then I cut the foam board down the middle to create two 4×4 components. This lets me rip smaller parts without having to set up the full-size 4×8 foam board. I duct-taped all the edges of the foam boards to protect them better during storage.

The foam boards store flat against the shop wall and take up very little space and my tabletop is protected when breaking down sheet goods.