Sump Pump Problems

Image: www.dunlapplumbing.com

Sump Pump Problems

As a contractor, I have seen my share of water damage caused by just 2 to 3 inches of water in a basement. Having a sump pump installed is cheap insurance.

Many times a homeowner will install their own pump and miss a few key install points. Often the failure of a sump pump can be traced to a few simple sump pump problems which usually point to installation mistakes.

My experience has shown that buying a high-quality sump pump that will operate for years without a major malfunction and installing it properly is the only way to go.

Tips to avoid sump pump problems:

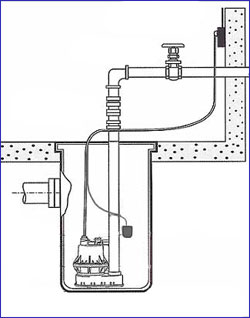

- A sump pump basin should be at least 18” round and 22” deep for it to work adequately with a pump.

- Smaller and narrower sump basins cause float/switch failures and more frequent pumping cycles.

- A sump pump should have a rating of a 1/3 to ½ hp rating.

- A1/3 HP sump pump has an average lift ability is 25 feet and the flow capacity is about 25 GPM.

- Too large of a pump will cycle on /off to often and have a shortened life.

Type of Sump Pump:

You get what you pay for in pumps so look for a high-quality pump with heavy cast metal housing. Cast metal dissipates heat buildup much better than a pump with a plastic or thin metal housing. In my opinion, a few good quality brand names are Liberty and Zoeller.

Power and Switch problems:

The leading cause of failure in most sump pumps tends to be with the float /switch. The switch of a sump will often fail to turn on because the pump has shifted inside the sump basin causing the float that operates the switch to lodge against the side of the sump basin.

Another reason could be a piece of debris interfering with the movement of the float /switch. It’s a good idea to manually check that your pump switch and float arm assembly move freely.

Tripping the electrical circuit breaker often results in a mess. It’s also not a bad idea to have your pump on a dedicated electrical circuit and not run a de-humidifier on that same circuit.

Airlock:

An airlock is another problem with sump pumps. If the pump shakes and vibrates or if it fails to pump it can almost always be attributed to pump air-lock.

When a sump pump turns off, the water in the discharge line between the pump and the check valve drains back into the sump. If the pipe between the pump and the check valve is solid, the air in the line will compress the next time the pump tries to empty the sump basin. This compressed air can prevent water from leaving the pump.

Image: sumppumpsusa.com

To solve this problem I always drill a small 3/16 inch vent hole in the side of the discharge pipe inside the sump hole. It’s a good idea to manually check to make sure that this hole is not obstructed or clogged.

Check Valve:

Other problems arise when the check valve fails to hold the water and the pump continually recycles. This fix involves replacing the check valve or diaphragm inside it.

Back up pumps:

I always suggest having a second pump [new] as a back up in case your pump fails. Often pumps fail during heavy flooding and the stores are quick to sell out.

I also recommend having a portable/backup utility pump with a long hose. store this pump nearby in case the water rises too fast and overwhelms your sump pump. This utility pump can be dropped in the sump hole to assist the sump pump.

The beauty of using a utility pump is that it gives you additional pumping capacity. The 1/6hp Simer utility pump I use has a pumping capacity of 1260 gallons per hour. I use this pump in a variety of areas: window wells, basements, sump holes, and rooftops, etc. the only issue with these backup pumps is that the pump does not shut off automatically and you need to unplug it.

Water level alarm:

One customer of mine has an alarm system that monitors for burglary as well as water. She currently has a sensor on the floor next to her water heater. On a recent visit to her house, I suggested that we add a second sensor on the discharge pipe in the sump basin. This way if the water rises too high, [i.e., the sump pump is not keeping up; she will be notified and could add her submersible pump to assist.