How to Make Plinth Blocks

How to Make Plinth Blocks

How to Make Plinth Blocks

I love using Plinth Blocks in finish carpentry especially when the door casings are ornate. Plinth blocks act as a decorative base for door trim, pilaster or columns and are often seen in higher end trim work and older homes where the trim and baseboard intersection do not visually meet well.

Plinth blocks stand proud at the bottom of the casing, adding a reveal, and shadow line depth between the vertical and base trim. “Plinth” is an architectural term used to describe a support for a column or base. The vertical trim or molding butts into the Plinth top, and the horizontal baseboard butts into the Plinth side.

Sizing Your Plinth [The Golden Rule]

For a Plinth block to look right, it needs to clear the baseboard and base cap height. The other issue is proportion. Plinth blocks look best, when the height is 1.5 to 2 times the width. Many designers follow the “golden rule” which is to make the height equal 1.6 the width.

Store Bought Plinths

Many lumberyards and mill-work companies sell or make plinth blocks that match the profiles of specific door trim molding they sell. This is an easy way to accomplish plinths in your design, as long as your baseboard trim work with the plinth you bought. In my experience, there are not many commercially available plinth block sizes available for all the different trim that I deal with. Sometimes making your own plinth blocks gives you the flexibility and versatility of making the exact height and thickness for whatever door trim you’re installing.

How to Make Your Plinth Blocks

How to Make Your Plinth Blocks

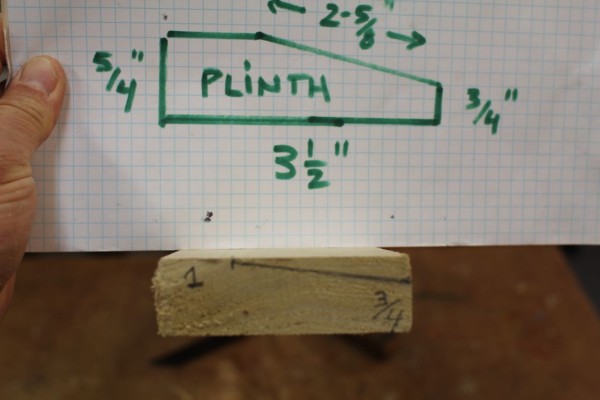

I typically use 5/4 trim for my plinth blocks. In this particular job I used 5/4 x 4 and duplicated the existing plinths found elsewhere in the home. These plinth blocks have a bevel that took the thickness from 1-inch down to ¾ inch, them to mimic the narrowing of the casing used.