How To Install Exterior Window Trim

Building and Installing Pre-Assembled Exterior Window Trim

This article will explain how to install exterior window trim by using a pre-assembly method. Pre-assembling trim is faster, more efficient, neater, and produces near-perfect joints every time. This approach is different from installing trim on the window one piece at a time, it requires a completely different way of working.

Pre-Assembly Surround vs Piece Meal Trim

Piece-by-piece trim installation requires you to travel back and forth between your miter saw and wall, or up and down a ladder or scaffold. Additionally, the joints are almost always off or not flush, due to the nailing flange or unevenness in the wall, which translates into uneven/open trim joints.

It’s far easier to build the trim surround as one piece on a flat surface. When installed as one piece it sits better with tight joints.

PVC Trim Is Rot Resistant

PVC trim boards are widely popular for being weather-resistant, termite-proof, and rot-proof, making them one of the most reliable materials for exterior building. One of the biggest advantages is that it doesn’t need to be painted.

Measuring and Fitting

Measuring pre-assembled trim should always be done off the window itself. You can accomplish this on the ground, prior to installation, or after the window is installed. When feasible, I prefer the former method. With multiple, same size, windows, this method can become an efficient, fast, best practice way to finish a project’s exterior window trim.

Pro Tip:

- When measuring horizontally, measure the furthest protruding part of the window. Take your measurement point to point to outermost point – and ADD 1/8” plus the thickness of your trim X2 to that measurement. This gives you the total length of the top trim and windowsill. This 1/8” measurement gives some adjustment room for fitting and sealant.

- When measuring vertically measure the furthest protruding part of the window. Take your measurement Point to point to the outermost point – and ADD 1/8” to that measurement, this will give you some adjustment room for fitting and sealant. This measurement is the length of your window trim.

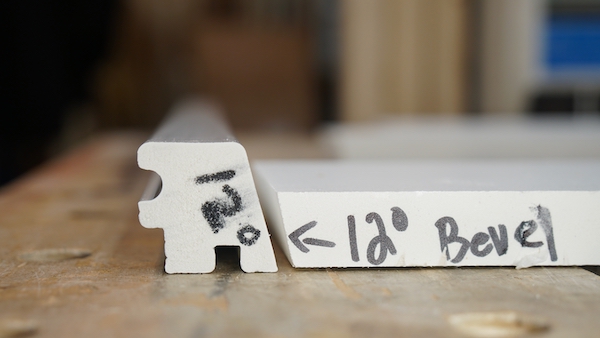

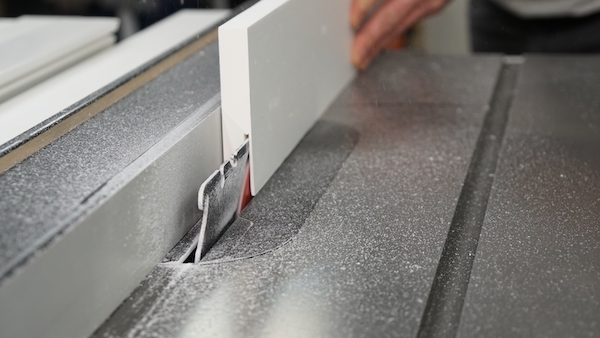

Bevel Bottom at Windosill and Cut “Rabbit” Channel for Nailing Flange

You will need to determine the bevel cut of your windowsill and cut the bottom of each leg trim to fit the sill. [bevel]

Pro Tip:

- Prior to cutting your rabbit channel mark the back of the leg parts to avoid errors. It’s easy to flip a board around and cut a bevel or a rabbit channel on the wrong end or edge. I mark the back the trim bevel end and rabbit edge to avoid these errors. Cut a rabbit channel on the back of the trim by making two cuts on a table saw. The rabbit width cut is usually ¼” wider than the nailing flange and 1/16-1/8” deeper than the thickest part. This rabbit creates a space for the nailing flange so the trim can sit tight to the wall sheathing, without rocking or interference.

Window Sill Material

Exterior PVC sill can be bought or made on-site; we chose to use a pre-made sill for this project. Windowsills typically have a 10–15-degree bevel to drain water out and away from the window. The sill should project out away from the window, leg trim, and siding for water management, off and away, from the house.

The bottom edge of the sill should have a drip groove installed to break the surface tension of the water and prevent the water from running back to the house siding. A rear groove under the backside of the sill allows for house siding to tuck up and under the sill for overlapping weather coverage.

Window Trim Surround Assembly

Preassembly requires eight [8] screws total. Each vertical window leg gets 2 exterior pocket screws [4 total] and PVC cement to secure the legs to the head. The windowsill to leg attachment will receive four longer, exterior-grade screws and glue.

Note – You should always use PVC cement adhesive to secure the joints and prevent separation or visible gaps between the boards.

The best practice to keep your joints tight, and boards secure is to use a combination of glue and mechanical fasteners.

- Drill two pocket holes into the tops of each window leg casing. Apply PVC cement to both parts being fastened and allow the glue to become tacky. The glue melts the PVC creating a permanent, new bond to each other.

- Align the vertical leg to the top casing and clamp so the joint is flush. Once your pieces are aligned, install the pocket hole screws. Repeat the process on the other end. The screws hold the joint tight, without the need for clamps. Note – Use pocket hole screws are rated for exterior, they’re easy to spot as they are blue in color.

Pro Tip:

If you have a pocket screw blow out because you drove it too far, leave it in place until the PVC glue has dried. Once dry, back out or remove that screw and fix it on the sanding stage. After assembly, sand off the glue, or any unevenness at the vertical leg and head trim joint.

Fastening the Windowsill

With the window trim assembly back side facing up, line up the back of the windowsill with the pre-cut nailing flange channels on the vertical legs. Clampdown the leg casing and drill 2 pilot holes through the sill into the leg casing. Use exterior screws, long enough to penetrate the leg casing by an inch, preferably more.

Installing The Trim Surround

Slide the trim assembly over the window frame, evenly splitting your reveal gap. Install 2-3/4” Cortex hidden fasteners every 16-20 inches apart.

The Cortex fastener bit installs the screw and creates a perfect hole to insert a PVC plug. When fastening, take care to drive the fasteners straight/perpendicular to the trim surface, so the plugs sit flat. Once the fastener is installed place a tapered PVC plug into the hole and tap it flush.

How To Install Exterior Window Trim | How-To Video