How to Choose Sandpaper

Using The Right Sandpaper

Image: Source

Using the right sandpaper is the key to a successful project

How to Choose Sandpaper Guide

Using the right sandpaper can make a job faster and less tedious .

Sandpaper is made by binding an abrasive material to a paper or cloth backing. Sandpaper comes in sheets, rolls, bands and disks.

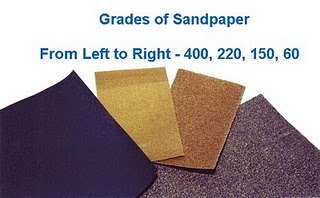

Using the right sandpaper means choosing the proper sanding grit. When talking about sandpaper “grit” we are referring to the number of abrasive particles per inch of sandpaper.

The lower the grit the rougher the sandpaper, the higher the grit number the smoother the sandpaper.

Using the right sandpaper means matching the grit with what you are trying to do. The following table is a general guide on how to choose sandpaper.

Sandpaper Grit:

40-60 Coarse Heavy sanding and stripping, roughing up the surface.

80-120 Medium Smoothing of the surface, removing smaller imperfections and marks.

150-180 Fine Final sanding pass before finishing the wood

220-240 Very Fine Sanding between coats of stain or sealer.

280-320 Extra Fine Removing dust spots or marks between finish coats

360-600 Super Fine Fine sanding of the finish to remove some luster or surface blemishes and scratches.

Aluminum Oxide and Garnet

The two used most often by carpenter and woodworkers are Aluminum Oxide and Garnet.

Aluminum Oxide exhibits a high degree of friability which means that when heat and pressure are applied it fragments. This is means that it creates new sharp edges which allow you to continue sanding longer than other types of grit.

Garnet tends to wear out a lot faster than aluminum oxide but produces a much smoother product. It does sand /cut slower. Garnet is an excellent choice for the final sanding of a project.

If you enjoyed this post, make sure you subscribe to my RSS feed or receive updates via email