Using a Scroll Saw to Make a Shop Sign

Using a Scroll Saw

What do you get a guy who has everything? Another tool? Does he really need any more tools (I’ve been in his shop)? I know! I’ll Use a scroll saw to make a shop sign as a gift. Happy Birthday Rob Robillard!

Using a Scroll Saw to Make a Shop Sign

I’ve always loved my scroll saw. It probably will never make me rich, but being able to sit in front of this machine in my shop is one of the most peaceful things on this earth. As much as I love the rhythmic hum of the saw, I also love the planning and creating part.

Sign Layout and Design

That part is a little tougher for me, because as my daughter Emma would tell you I’m “creatively deficient”. Lucky for me I have my daughter Emma. At 15 years young she has quite the eye for design, color and symmetry that I seem to be lacking at times. I call her my creative consultant. She calls herself the reason all my designs don’t look absolutely horrible. She is as tough on me as they come, but I couldn’t ask for a better consultant, and together we’ve designed some beautiful pieces.

So when I was invited to Rob’s big 50, it was time to get my mind to work. I knew what I wanted to use his cupola logo to make him a shop sign, but I needed some design consultation. Emma thought my design was “alright…not great”, but at least she helped to keep my colors in line and my design from getting “out of hand”.

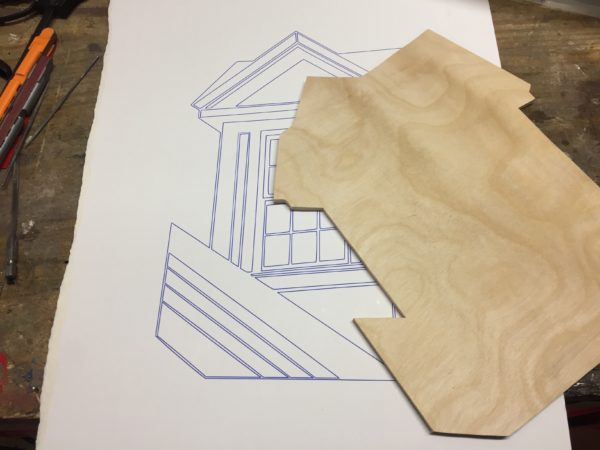

Silhouette Vectoring Program

The first step for me, after thinking of a design in my head, is to vector it on the computer. Using a Silhouette vectoring program I transfer all my thoughts onto the computer. The vectoring program (which is extremely easy to use) allows me to resize my design, and see what it will look like. I then use poster board and a sketch pen to transfer the vector. I do this using the Silhouette Cameo 3 plotter/cutter. This machine is probably one of the best purchases I ever made ($300). It is extremely easy to use with a very easy learning curve, and it can do a million things, from penning out a vector to cutting vinyl. It is worth its weight in gold.

Once the vector is penned I can actually see in real size what my project will look like. Those drawings are saved so that I can use them as a layout template later. My last step on the computer, once I am happy with the penned drawing, its time to cut the same design out of vinyl. For this purpose I use Oracal 631 removable vinyl or Orafilm, which is a stenciling film.

Scroll Saw Work

Scroll Saw Work

After cutting and weeding the vinyl, I then transfer it to wood. The vinyl serves as my guide while cutting and sanding the pieces. Using a scroll saw takes a whole bunch of practice, a lot of patience and a little strategy. Inside cuts need to be made first, thin pieces have to be cut extremely slow, and it’s a whole lot easier to sand off a little later than try and add on filler or wood. Inside cuts are done by drilling a strategically placed access hole, releasing the blade clamp, sliding the blade through the hole, reattaching the blade, and making the cut.

If there are a hundred inside cuts, than you go through this process a hundred times. Depending on the thickness and type of material I am cutting and the tightness of cuts that need to be made determines which blade I use in my saw. For the most part I use a #5 reverse scroll saw blade when cutting. As cuts are made, pieces are aligned on the template so I remember where they go which is a lot easier than trying to figure it out later, especially when a lot of pieces look like the others. As I said before, this part of the process is the most peaceful.

Carefully Sanding

Carefully Sanding

After all the pieces are cut out I then spend time sanding and filing pieces to get them to look good, removing burrs and blade marks. This part is handwork mostly. Although I will use my Dremel with a sanding drum at times. The work is usually performed with mini hand sanders, needle files and my trusty Exacto knife. Sanding has to be done extremely carefully as some of the pieces are thin and fragile. You always run the risk of breaking a piece of wood, especially when you work with such small pieces. If you are painting the piece, glue and a little filler will work to put it back together. If the piece is going to remain natural or unfinished then back to the saw you go to cut another one.

Airbrush Painting

Airbrush Painting

Painting takes the most time. I usually will start by priming the pieces with a latex primer. Being that the primer “soaks in” I usually will use a small brush. After the primer has dried, it’s on to color. Depending on the piece I am doing, I will either use a roller, brush or my airbrush to apply the color. My airbrush is an Iwata Eclipse HP-CS airbrush. The airbrush is a great tool to paint small pieces, its spray can reach into really tight crevices on the pieces. No glob’s of paint and no brush marks.

The downside of the airbrush is that the paint has to be thinned out to be used in the airbrush, resulting in you having to use multiple coats to cover a project. Due to this, a lot of times I will spray the first coat, brush a thicker second coat, and finish the project with the airbrush on the third coat to smooth out the finish. For my airbrush paints I use Createx and Wicked colors. With Rob’s project I also added a candy finish to the letters using a blood red dye mixed with a clear. The biggest problem with using an airbrush is….air!! Even though an airbrush only uses between 20-40 psi., this air pressure is enough to launch the letter C clear across the shop (believe me I know). To avoid this, I place two-sided tape on my spray area to hold my pieces in place while being sprayed.

Making the plaque

Obviously the pieces for most of my work would look rather tacky glued to the wall by themselves, so onto building the foundation. Plaque size and shape are really dependent on the design size and the feeling I’m looking to capture in a piece. If it’s a formal piece that’s going to be something hanging in an office, I may use a certain design. But if I make a whimsical piece to hang in someone’s home, my design may be totally different.

Plaque material is also something that varies. Once again depending on the piece, it design, and color, really determines what I use for material. My personal favorites to use for the plaque are edge-banded plywood, or in the case of Rob’s plaque, I used a pre-made pine panel. For the most part I like to stick with material that is ½ – ¾” thick, so that I can securely attach the cleat that I use to hang the plaque on the wall. For Rob’s plaque I chose to use the pre-made pine panel, which I cut to size with my track-saw. After scalloping the corners with a jig saw and sanding, I added a cove to the edge of the plaque with my palm router.

Assembly

After the paint has dried, repairs have been made, and the plaque base has been fabricated, I move on to putting the design on the plaque. This usually is the tricky part, especially when there are numerous pieces. The two adhesive that I use are Titebond translucent glue and Titebond CA gel with a 50-60 set time. I usually save the CA for tiny pieces that I want to make sure will never fall off, whereas the larger pieces usually will get a pin nail or two. Setting the pieces in place requires a little pre measurement, sometimes a few faint pencil marks that are erased later, and the template that I started with. Setting the pieces is done otherwise by eye. Titebond translucent glue allows me usually about 4-5 minutes to adjust the pieces as I set them in place, and any squeeze out is easily cleaned up with a wet cloth. Once the design has been put together and the glue has been given 15-30 minutes to set I will add pin nails to most of the pieces to make sure that humidity or temperature changes will never cause a piece to “pop off”.

Urethane Finishing

After everything has been vectored, cut, sanded, painted and glued, there’s one important step to take. Finishing is pretty straightforward. If it’s going to be in sunlight or exposed to elements then Helmsman spar urethane is my choice. Although Spar Urethane can yellow your work, it is formulated with UV protection to protect your work from the damaging rays of the sun. If my work will not be exposed to the elements or in a relatively stable environment, then acrylic clear or enamel clear is what I use. Usually 3-4 thin coats with a spray can will suffice.

French Cleat and Signature

French Cleat and Signature

I usually add a hanger to the back of the plaque so it won’t be left on the floor. In my opinion, the Hillman Hangman picture hanger is the best one to use. It is easy to install, it can hold a ton of weight (12 inch hanger- 100 lbs.) and this French cleat style hanger allows you to remove the plaque easily to clean or paint. No work of art would be complete without an artist signature, so I always sign and date my works on the back.

Using a Scroll Saw to Make a Shop Sign is a fun way to create a gift for a friend, especially and old guy like Rob! Now I need to start thinking about what I’ll make him when he turns 60….hmmmm.