IRWIN Marples Woodworking Chisel Set

Every carpenter needs chisels, and the IRWIN Marples Woodworking Chisel Set (Model #M444SB6N) fits the bill well for many of them. Here’s a little context to explain why I say that.

Six main carpenter types

I separate carpentry into the following general categories, from most rough to least: timber framing, stick framing, finish (trim) work, cabinet making, furniture making, high-end heirloom crafting. The first three are what are usually thought of as the “carpentry” trades, and they are done on-site. The latter three are usually thought of as the “woodworking” crafts, and they are performed in a shop. Of course there are several sub-categories within each of these six broad buckets, and they can overlap a bit. (There are also unusual carpentry trades like ship building, but shipwrights are pretty rare.)

Framers (timber and stick) need a chisel in their pouch for the clean-up of cuts, maybe to form a rough mortise or two, and sometimes to just hack away some un-needed material. These chisels are usually reasonably rough-use tools sporting full tangs, and designed to be whacked with a heavy (perhaps framing) hammer. Irwin makes these kinds of chisels too, but they aren’t as widely used or a general-purpose as the IRWIN Marples Woodworking Chisel Set that we’re looking at here (we’re specifically looking at the six-piece version here). These particular chisels are designed for the next three types of carpenters, engaged in finish (trim) work, cabinet making, and furniture making. It’s exactly because of their broad application that I wanted to look at them.

For most of us

Chisels generate a lot of emotion in the woodworking trades. I need to be clear that I’m not looking at this chisel set as it might apply to high-end (sometimes called “fine”) heirloom woodworking – done only with hand tools of course. One, I’m not qualified. Two, once you enter this rarefied realm, chisels (and hand planes) take on a mystical, divinely-imbued quality, and are treated as objects of reverence and worship. One is expected to spend north of $100 per chisel here, to accept nothing less than chisels made of the finest unobtainium steel alloy…or to manage to discover one of the few remaining vintage Marples chisels from the golden age of hand tools at a garage sale by the estate of a 100-year old recently deceased woodworker. In other words, we’re into the realm of art and craft for its own sake. There’s a lot to be applauded about the men and women who keep that niche alive, and much to be coveted in their skill, but they’re not me; they’re not most of us.

Rather, I’m looking at the IRWIN Marples Woodworking Chisel Set as reasonably-priced tools that are meant to be used and not babied, by working carpenters. Possibly to be passed down to the next generation, but if they get damaged or find legs they can be replaced without too many tears.

Basic specs

- Slim, contoured polypropylene handles

- Designed for use with a wooden mallet or the palm of the hand

- High carbon steel

- Hardened to RC 57 – 62 for a minimum distance of 2/3 of the length from the cutting edge to the shoulder

- Bevel angle of 25 degrees

- Woodworking Chisel 6-piece Box set includes one each of the following sizes: 1/4-in, 3/8-in, 1/2-in, 5/8-in, 3/4-in and 1-in

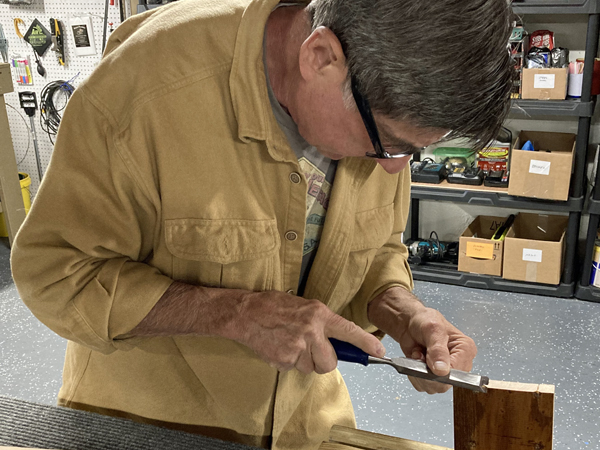

Although a wooden mallet is the traditional tool used for striking chisels, I prefer a hard rubber faced hammer as you see in the picture below. You shouldn’t use a steel hammer with these chisels.

Uses

I’d expect the IRWIN Marples Woodworking Chisel Set to be used by trim carpenters to shave (called “paring” when it’s done with a chisel) small bits of molding for a perfect fit, by cabinet makers to form or clean-up hinge mortises, and by furniture makers to shape joined pieces. In these cases the chisels would complement efficient power tools – used when the power tool can’t do the job or is too much hassle to set up.

Geometry

The IRWIN Marples chisels are “bench” length chisels (in contrast to shorter “butt” length chisels, and taper in thickness from the rear to the edge. They are of the modern design with a flat back, flat top, a “sidewall”, and a bevel connecting the sidewall to the top (“modern”, at least, compared to chisels in use during the James Monroe administration). The main limitation of this design is found primarily in heirloom-quality hand crafting of fine furniture, in that the sidewall prevents the chisel from cleaning out the corners of dovetails completely. Outside of that application however, the modern design is multi-purpose and well adapted to the spectrum of carpentry tasks for which working chisels are designed (hence its popularity). If you do find yourself having to clean out the acute angle of the odd dovetail, they will get you close enough in most cases (and a simple utility knife will finish up the task easily).

The edge and back

The IRWIN Marples chisels came sharp. But like almost all chisels, they need a touch-up to get them ideally sharp. I spent only a couple minutes on some stones to get each chisel just to hair-shaving sharp, which is also just about to freely-held paper slicing sharp. I didn’t continue to take the chisels all the way to hair-popping sharp because it wasn’t necessary for any work that I do. The standard indicator of whether a chisel is sharp enough for most work is that it will pare slices and slivers of soft wood (pine usually) end grain easily. These did.

A perfectly flat back can be necessary for very fine work, and slightly concave back will work too. I took the stones to the back of each chisel and was glad to see that each was slightly concave. That meant that all I had to do was make sure that the back was good and flat near the edge, and that required less than a minute for each chisel.

Balance

Polymer-handled chisels like these always feel slightly handle-heavy in the hand when working them (even though the actual balance point is mid-way along the length). Whether that’s good or bad for you is a matter of preference. Since most carpenters don’t use a chisel all day long they may not even develop a preference (I haven’t). In any case I found these chisels to be comfortable to work with. (I should note that I often “choke down” on a chisel when using it, and suspect that many users do, which changes the felt balance.)

Chopping and edge retention

It’s amazing how fast a keen edge can lose its razor-sharpness. One test that wood workers often perform with chisels is to get them paring sharp relative to pine end-grain, chop a bit of hardwood, and then see if the chisel will still pare the end grain. Mimicking what I’ve seen them do, I used the ½-inch chisel of this set to chop ten ¼-inch deep cuts in hard maple. And…the chisel still easily pared the end grain. Pretty good.

Nonetheless, a wood worker will touch up the edge of his or her chisel several times an hour if they are using the tool for an extended period. This is sound practice. As one of the most knowledgeable people regarding working knives once told me, “The key to sharpening a knife [or chisel] is to not let it get too dull to begin with.” This way, you are simply touching up the edge of the bevel – which is quick and easy, not re-grinding the bevel itself – which is difficult and time-consuming.

Sharpening

All edged tools need to be sharpened, and sharpening requires a set of sharpening stones. True, some brave souls will sharpen their chisels on a bench grinder (or even angle grinder), but that requires a steady hand, a delicate touch, and a strong constitution. Better in my opinion, and far less prone to ruining the tool, is a good set of stones. The subject of sharpening stones is complex, and it’s outside the scope of this review. What I’ll say here is that for plane blades and chisels, diamond stones are preferred to aluminum oxide, silicon oxide, or natural stones because the kinds of stones will “dish” over time; I’ve ruined a chisel or two by trying to sharpen them on a dished stone.

IRWIN specifies the steel in these chisels as “high carbon steel”. (Of course all steel is iron combined with some carbon.) The specified hardness of 57-62 Rockwell feels accurate to me given how the chisels sharpen up.

Choosing a steel, and the hardness to temper it to, is a balancing act on the part of the manufacturer. Steels that can take a very sharp edge are generally more expensive than ones that can’t (this is especially true for “stainless” steels). Hardness increases edge retention but makes sharpening more difficult. In managing this balancing act, it strikes me that IRWIN has chosen well. These chisels sharpen without too much effort and hold an edge for a good working time. They are very reasonably priced, too.

Bottom line

Every review of the IRWIN Marples chisels that I’ve read agrees that these chisels are a really good deal for carpenters and occasional/hobbyist wood workers. I also agree. Wood working is not a religion to me, and I probably refinish more pieces than I build or repair. For those tasks, and for my other carpentry, these very reasonably-priced chisels are all I could want.

Normally $79 at Lowes, but on sale for $45 as I post this (which is a steal!).