Best Cordless Track Saw Comparison

Best Cordless Track Saw Head-To-Head 2026

Looking for the best cordless track saw? You’ve come to the right place! We’ve tested 12 of the top models, evaluating them across key areas like cut precision, runtime, ergonomics, features, and value. After putting each saw to the test, we’ll crown the Best Cordless Track Saw based on overall performance.

In our previous Track Saw head-to-head in 2020, five models were available. Since then, the market has more than doubled with new saws and some upgrades to original models.

This cordless track saw head-to-head includes 12 saws from:

Best Cordless Track Saw | Specifications

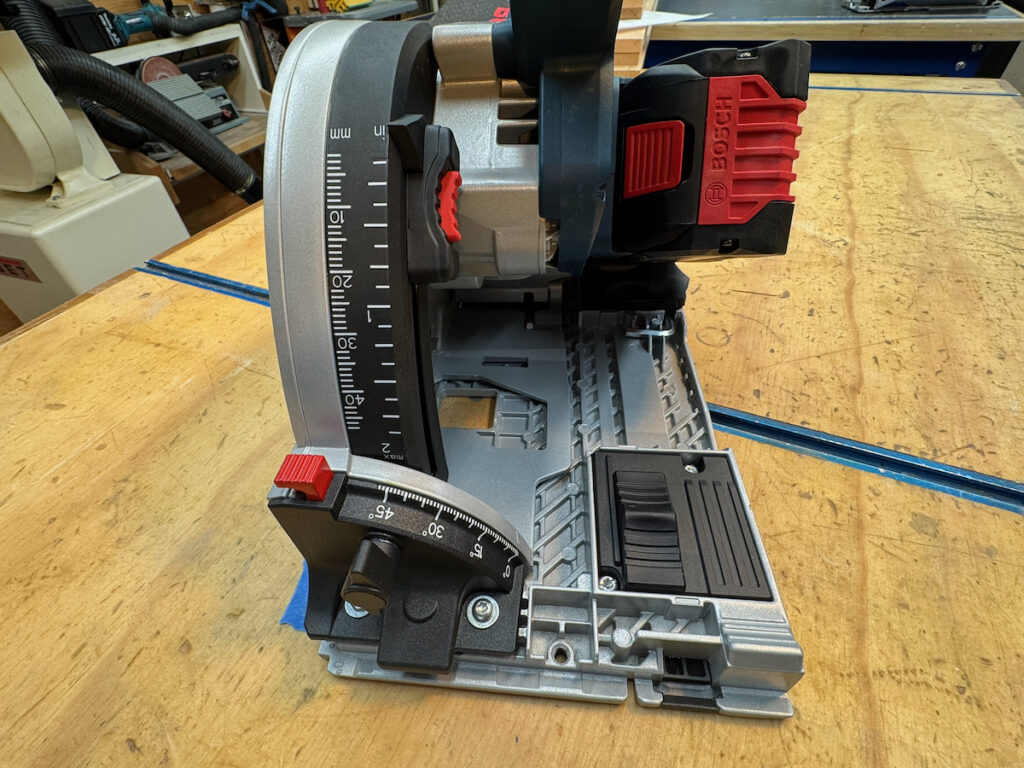

Bosch

- Model Number: GKT13-20GCL14

- Volts: 18V

- Blade Size: 5-½”

- RPMs: 5500

- Max Cut Depth @ 90°: 2”

- Max Cut Depth @ 45°: 1-¼”

- Max Bevel Cut: 47°

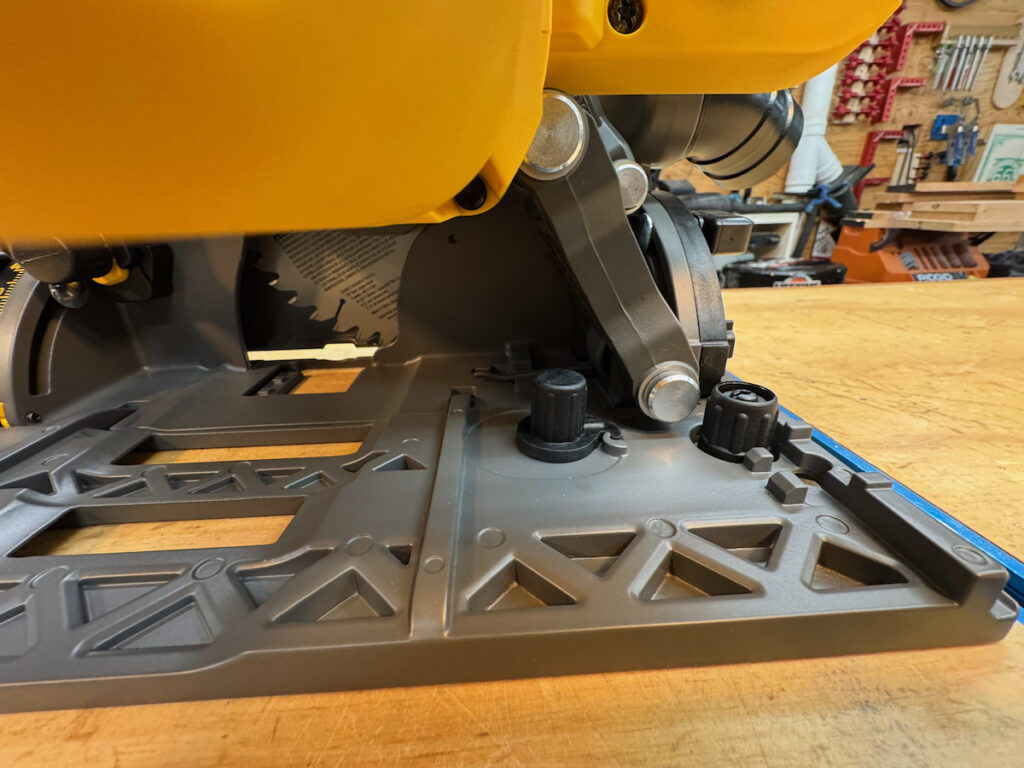

DEWALT

- Model Number: DCS520B

- Volts: 60V

- Blade Size: 6-½”

- RPMs: 4200

- Max Cut Depth @ 90°: 2-⅛”

- Max Cut Depth @ 45°: 1-⅝”

- Max Bevel Cut: 47°

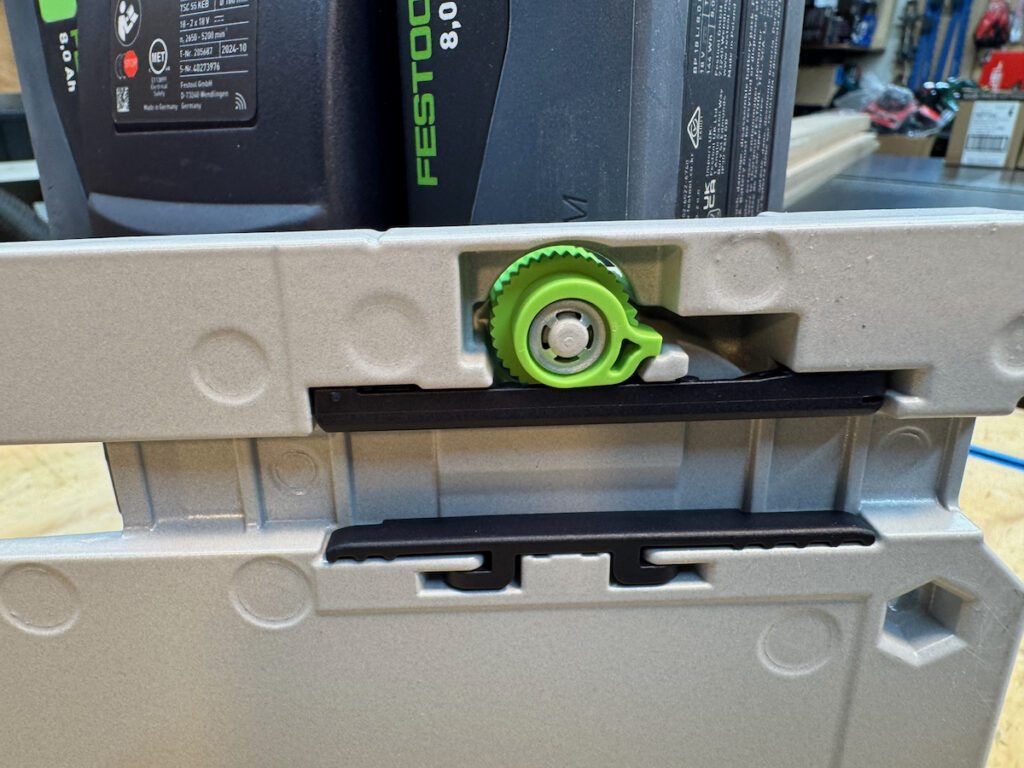

Festool

- Model Number: TSC 55 KEB

- Volts: 36V (two 18V)

- Blade Size: 6-½”

- RPMs: 5200

- Max Cut Depth @ 90°: 2-⅛”

- Max Cut Depth @ 45°: 1-11/16”

- Max Bevel Cut: 47°

Hilti

- Model Number: SC 6WP-22

- Volts: 22V

- Blade Size: 6-½”

- RPMs: 6000

- Max Cut Depth @ 90°: 2-¼”

- Max Cut Depth @ 45°: 1-⅝

- Max Bevel Cut: 47°

Kreg

- Model Number: KPTPS100A

- Volts: 20V

- Blade Size: 6-½”

- RPMs: 4200

- Max Cut Depth @ 90°: 2-⅛”

- Max Cut Depth @ 45°: 1-½”

- Max Bevel Cut: 47°

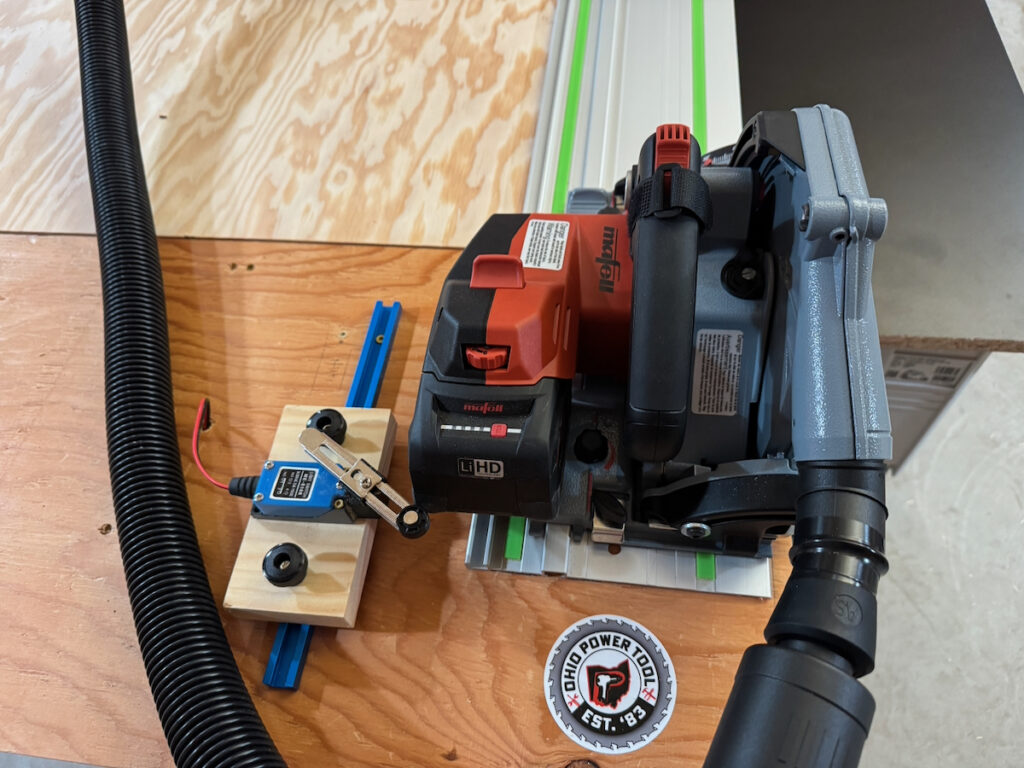

Mafell

- Model Number: MT 55 CC

- Volts: 18v

- Blade Size: 6-½”

- RPMs: 5930

- Max Cut Depth @ 90°: 2”

- Max Cut Depth @ 45°: 1-⅜”

- Max Bevel Cut: 48°

Makita LXT

- Model Number: XPS01Z

- Volts: 36V (two 18V)

- Blade Size: 6-½”

- RPMs: 6300

- Max Cut Depth @ 90°: 2-3/16”

- Max Cut Depth @ 45°: 1-9/16”

- Max Bevel Cut: 48°

Makita XGT

- Model Number: GPS01Z

- Volts: 40V

- Blade Size: 6-½”

- RPMs: 4900

- Max Cut Depth @ 90°: 2-3/16”

- Max Cut Depth @ 45°: 1-9/16

- Max Bevel Cut: 48°

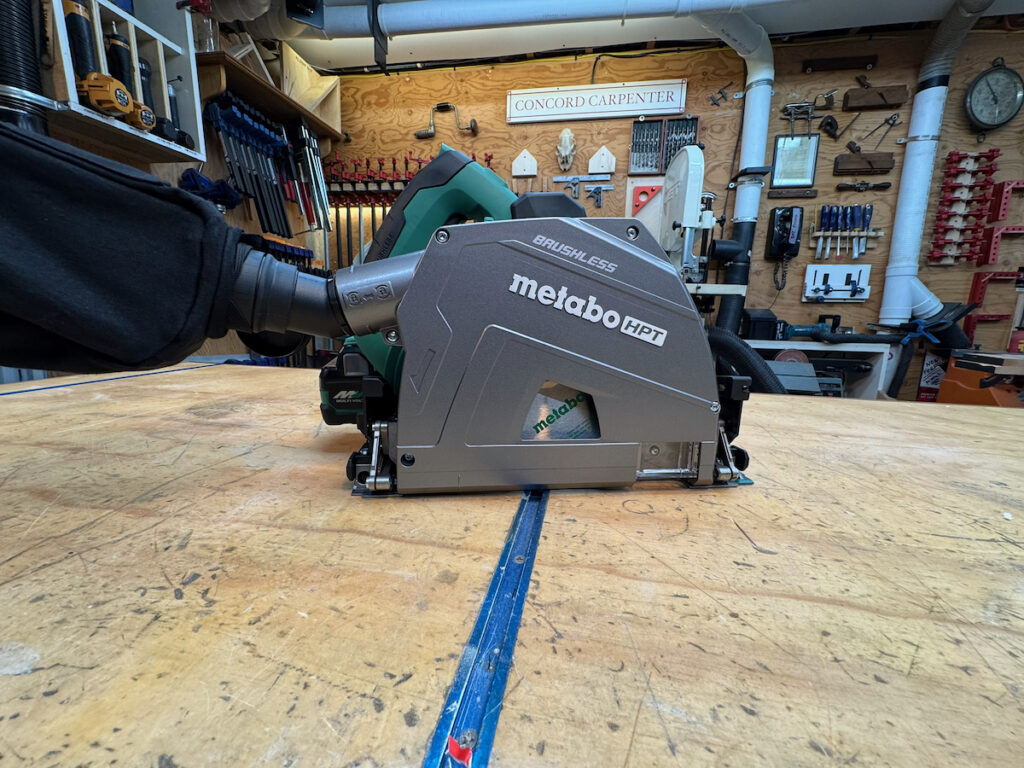

Metabo HPT

- Model Number: C3606DPAM

- Volts: 36V

- Blade Size: 6-½”

- RPMs: 5200

- Max Cut Depth @ 90°: 2-9/16”

- Max Cut Depth @ 45°: 1-11/16”

- Max Bevel Cut: 46°

Milwaukee

- Model Number: 2831-20

- Volts: 18V

- Blade Size: 6-½”

- RPMs: 6300

- Max Cut Depth @ 90°: 2-3/16”

- Max Cut Depth @ 45°: 1-⅝”

- Max Bevel Cut: 48°

Ridgid

- Model Number: R48630B

- Volts: 18V

- Blade Size: 6-½”

- RPMs: 5000

- Max Cut Depth @ 90°: 2-¼”

- Max Cut Depth @ 45°: 1-⅝”

- Max Bevel Cut: 47°

Ryobi

- Model Number: PTS01B

- Volts: 18V

- Blade Size: 6-½”

- RPMs: 4300

- Max Cut Depth @ 90°: 1-15/16”

- Max Cut Depth @ 45°: 1-7/16”

- Max Bevel Cut: 48°

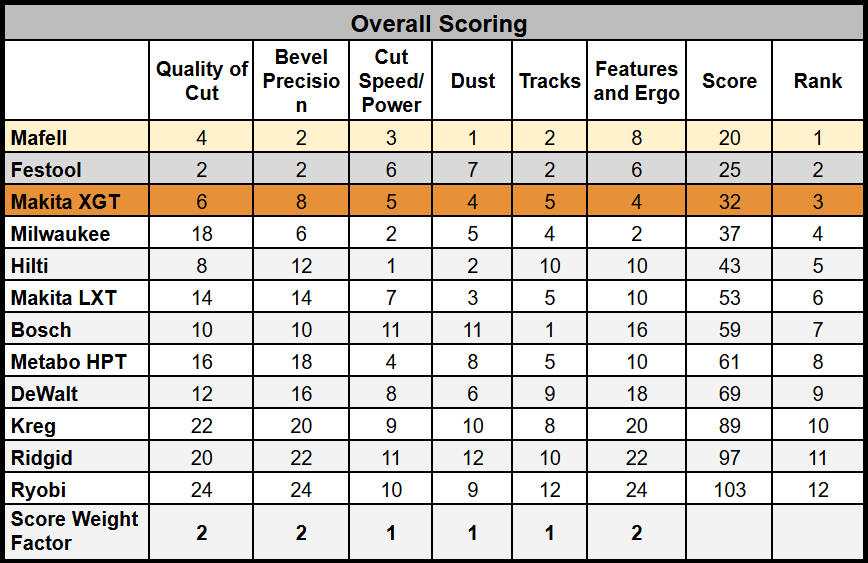

Best Cordless Track Saw | Evaluation Format

We evaluated the saws across several categories and ranked them to crown the Best cordless track saw based on the overall results.

The categories we evaluated were:

- Accuracy

- Quality of Cut

- Cutting Power

- Features

- Ergonomics

- Dust Collection

- Track Evaluation

- Price / Value

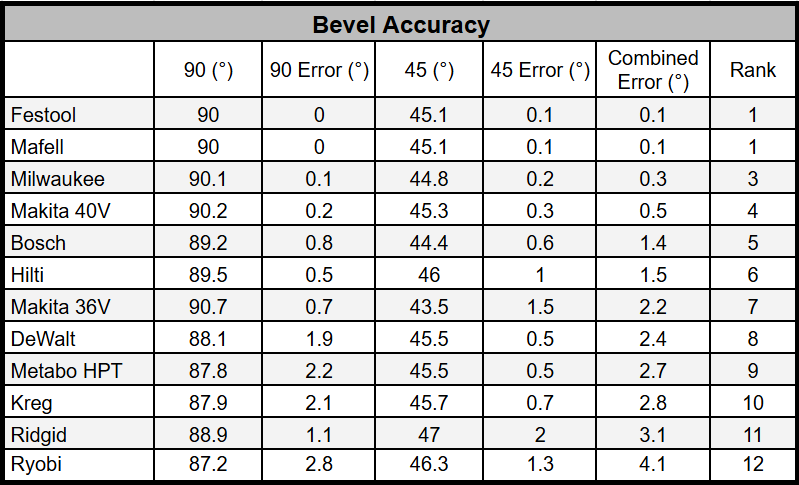

Track Saw Accuracy | Winner – Festool and Mafell

We tested the accuracy of the saws out of the box at both 90 and 45-degree bevels. While some higher-end models allow you to fine-tune the blade angle relative to the bevel markings and hard stops, we wanted to compare the saws right out of the box for accuracy and precision.

Each saw was equipped with new fine finish OEM blades, and we used Sugar Maple with a hardness of 1450 [on the Janka Scale] as our cutting medium.

What is the Janka Scale?

The Janka Scale measures the force (in pounds-force, lbf) needed to embed a steel ball halfway into the wood, indicating its dent resistance.

Each saw cut a 90 and a 45-degree rip in the Maple, producing a 90 and 45 side not influenced by factory milling or competitors’ cuts. The angles were then measured using a digital angle scale and scored.

Based on our cutting measurements, three track saws clearly separate themselves from the rest of the field. Festool and Mafell sit tied at the top for precision, each earning a combined error score of just 0.1 degrees. Both saws hit the 90-degree cut perfectly with zero measurable error and were nearly flawless at 45 degrees. This level of consistency highlights the exceptional engineering and calibration behind both systems and reinforces why they are often considered the benchmark for accuracy-focused users.

Right behind them is Milwaukee, with a combined error of 0.3 degrees. While not quite matching the near-perfect results of Festool and Mafell, Milwaukee still delivered impressively tight tolerances, with only 0.1 degrees of error at 90 degrees and 0.2 degrees at 45 degrees. That performance puts it well ahead of the majority of the field and makes it a standout option for job site users who need high precision without stepping into the highest price tier.

Overall, these top three saws demonstrated the most reliable and repeatable accuracy in our testing, making them the best choices for precision-critical cutting tasks.

Saw Blades Used During Precision Test

We used manufacturer OEM finish blades for our precision cutting testing. The list of blade are below:

- Bosch Precision Pro 42T General Purpose Fine Cut

- Dewalt FlexVolt 42T Fine Finish

- Festool 42T Fine Finish

- Hilti Ultimate 24T

- Kreg ICONIC 40T

- Metabo HPT 42T Finish

- Mafell 48T TCT Finish

- Makita 56T Max Efficiency

- Milwaukee 40T Finish

- Ridgid 40T Finish

- Ryobi 40T Finish

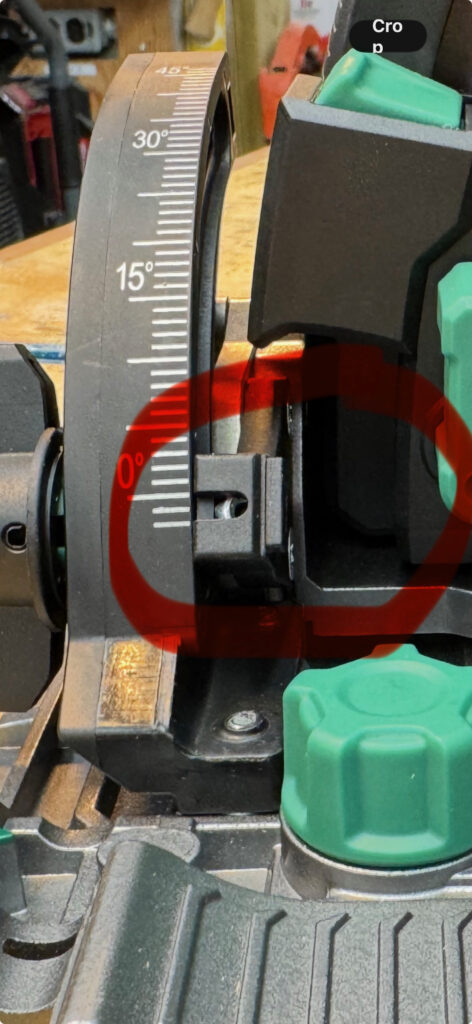

NOTE – We noticed that some of these saws can have some flexion when adjusting bevels. For example, we noted that the Hilti, when adjusting into the 90-degree setting, can easily and unknowingly be pushed/set past 90 degrees. Into a negative setting.

Quality Of Cut | Winner – Festool

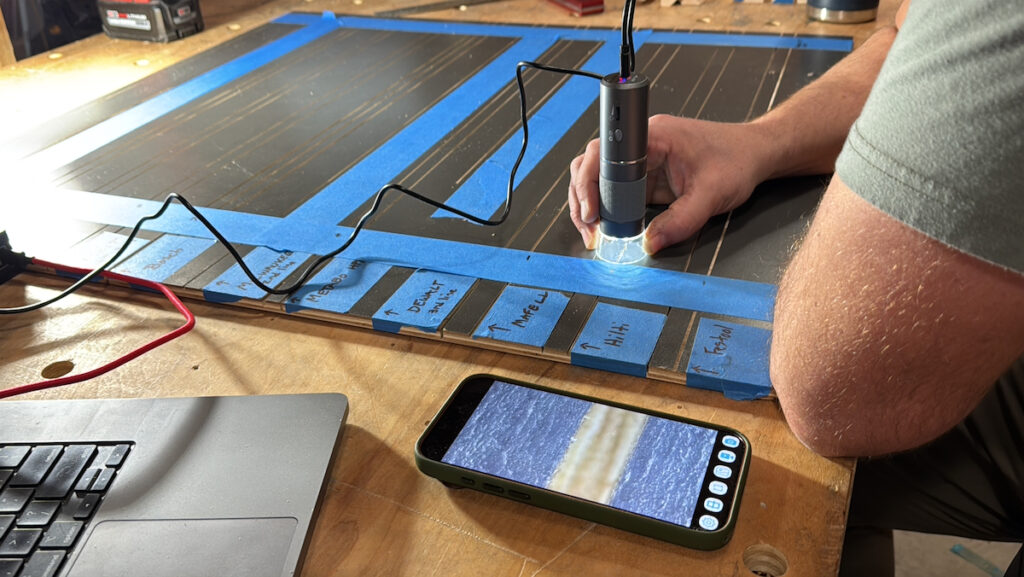

We used two methods to evaluate the quality of the cut:

- Cutoff maple strips from our precision testing.

Cuts are made into pre-finished cabinet panels. - Using angled lighting, magnification goggles, and a USB microscope, we evaluated the mill marks the saws left on the Maple strips and additionally noted any tear-out in pre-finished cabinet panel rips.

Festool took first place, delivering the cleanest cuts overall with virtually no visible mill marks and exceptional control of tear-out, even in the pre-finished panels.

Mafell followed closely in second, matching Festool in smoothness on solid maple and showing excellent edge integrity with only minimal panel tear-out. Both of these top performers require virtually no sanding on the cut surface.

Makita XGT secured third place with the Hilti just behind. The finishes on the maple cuts were smooth to the touch, and only under close inspection could visible cutting marks be seen, requiring very minimal sanding.

The rest of the field produced increasingly visible cutting marks as well as a rougher texture that can be felt when running a hand over the cut surface. The bottom three performers would require excessive sanding for a finished project.

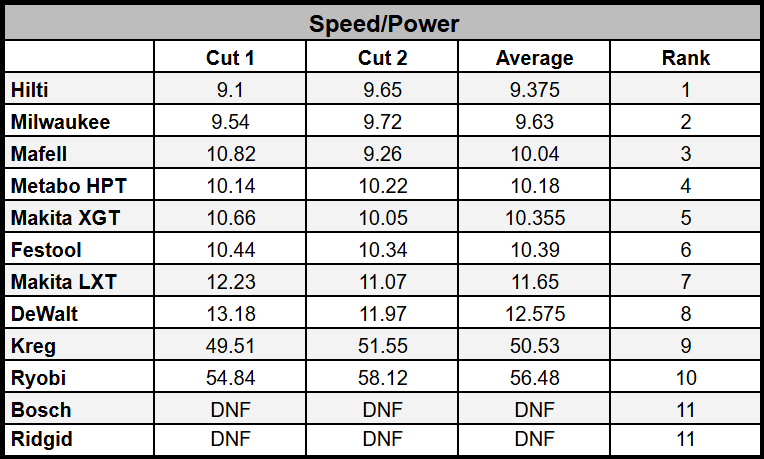

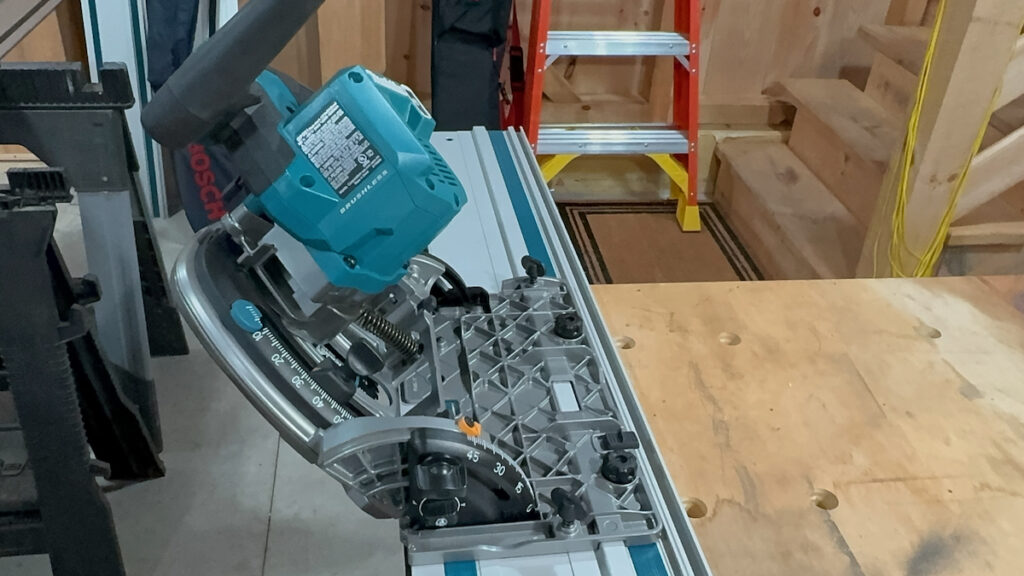

Track Saw Cutting Speed and Power | Test Procedure

While track saws are used for the “money cuts” where precision and straightness matter the most, cutting power still matters for those harder and thicker materials. Cutting speed depends on factors like blade width, tooth design, motor speed, torque, and the force applied by the user.

As the blade moves through material, resistance increases, requiring more power to maintain speed. Excessive force or a dull blade slows the saw. More powerful saws better overcome resistance, remove material efficiently, and maintain faster cut speeds.

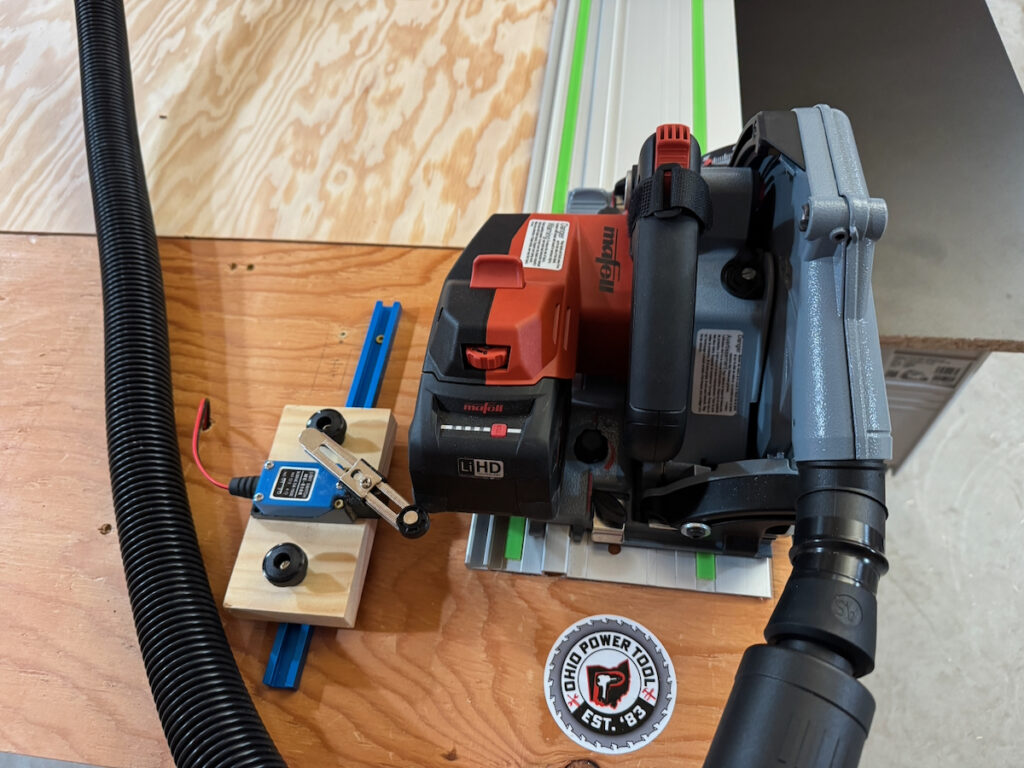

Speed-Test Setup

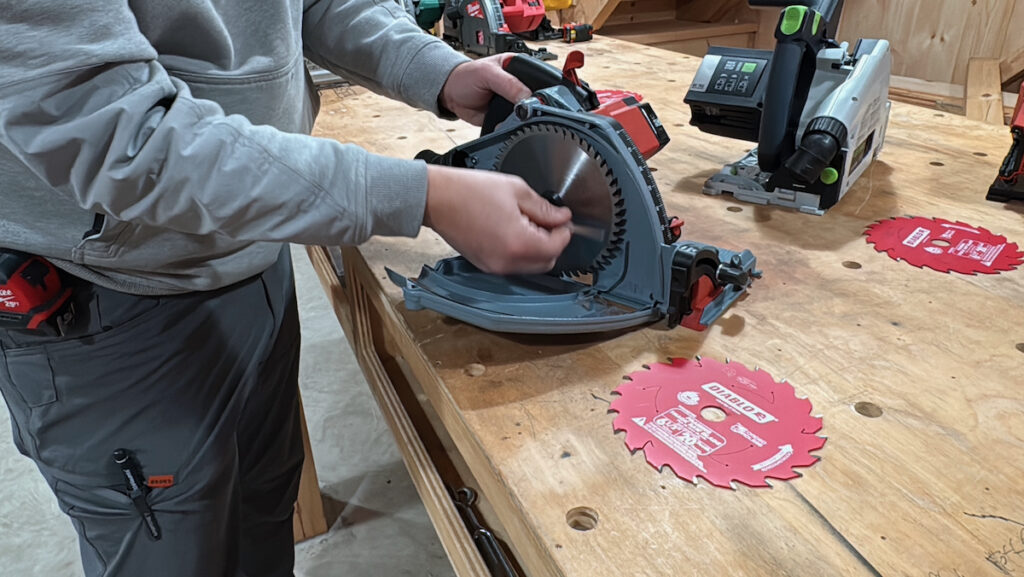

To minimize cutting variables and accurately test the speed of the saws, we used Diablo 20T Framing Track Saw blades on all the saws. This ensured that blade quality would not be a differentiating factor in performance testing.

We mounted the saws on a track saw rig and attached a drop weight pulley system to each saw to eliminate human error and ensure consistent cutting and tracking across all tests. An 8.5-pound weight was attached to a series of low-friction pulleys with the other end onto the track saw. This setup allowed for a controlled force to be applied during the cuts.

Testing Procedure

Each saw was fitted to the track to eliminate side-to-side slop, set to its highest RPM, full blade depth, and a fully charged battery was used. The cutting process involved several cuts through the plywood for each saw, with an average time scored. Micro-switches were used to control the start and stop times of each cut, again reducing human error.

After each cut, the track system was thoroughly cleaned of sawdust and debris, then lubricated with silicone spray before the next run. This ensured that the track remained smooth and low-friction throughout the test.

Cutting Speed and Power Test | Winner Hilti

Hilti delivered the strongest overall performance with 9.4 seconds and maintained blade speed exceptionally well throughout the cut, indicating excellent motor torque and power management.

Milwaukee matched Hilti closely, coming in at 9.6 and proving equally capable of sustaining high blade RPM under load. The saw showed minimal bogging during the cuts, demonstrating cutting delivery and efficiency. Taking third place was Mafell at 10 seconds. The top 6 saws showed a very tight grouping in cutting performance, with just a second separating the top half of the field. The Makita LXT and the

DEWALT was just a bit slower, but still cut the material smoothly. The Kreg and Ryobi both took significantly longer to complete the cut, but were still able to cut the full length in under a minute. Bosch and RIDGID both produced DNFs for different reasons. The Bosch is the only saw in the field with a smaller 5 ½” blade. The Bosch bogged down and stalled when pulled through the double-layer ply material. It was tested at a single layer and had no issues. Despite this, the team concluded that the Bosch is a premium, well-engineered, feature-rich saw that ranked in the top five for cut quality and precision.

The RIDGID, unfortunately, produced significant deflection, resulting in the blade binding.

This was repeated both on the rig and by hand ONLY when cutting the 2 layers of ply. Single-layer cutting had no issues.

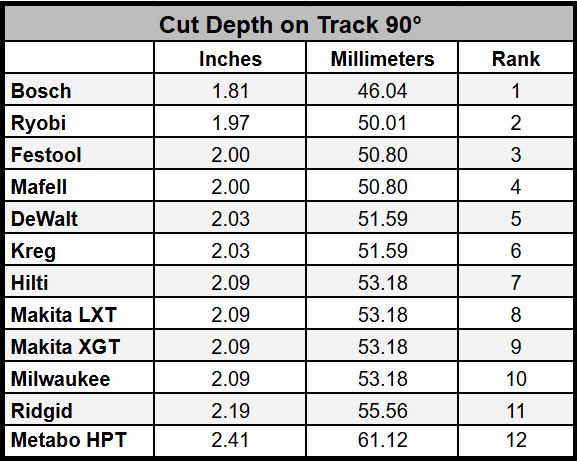

Maximum Cutting Depth | Winner – Metabo HPT

Looking strictly at maximum cutting depth, a few saws clearly separate themselves from the pack.

At 90°, Metabo HPT takes the top spot outright with an industry-leading 2.6 inches of cut depth. That extra capacity is meaningful when breaking down thicker stock, stacked sheet goods, or working beyond standard cabinet materials. Right behind it is Ridgid at 2.25 inches, followed closely by Hilti at 2.24 inches. There is a notable tie just below that group. Makita 36V, Makita 40V, Festool, Kreg, and Milwaukee all cluster around the 2.09-inch range, delivering very similar depth capacity.

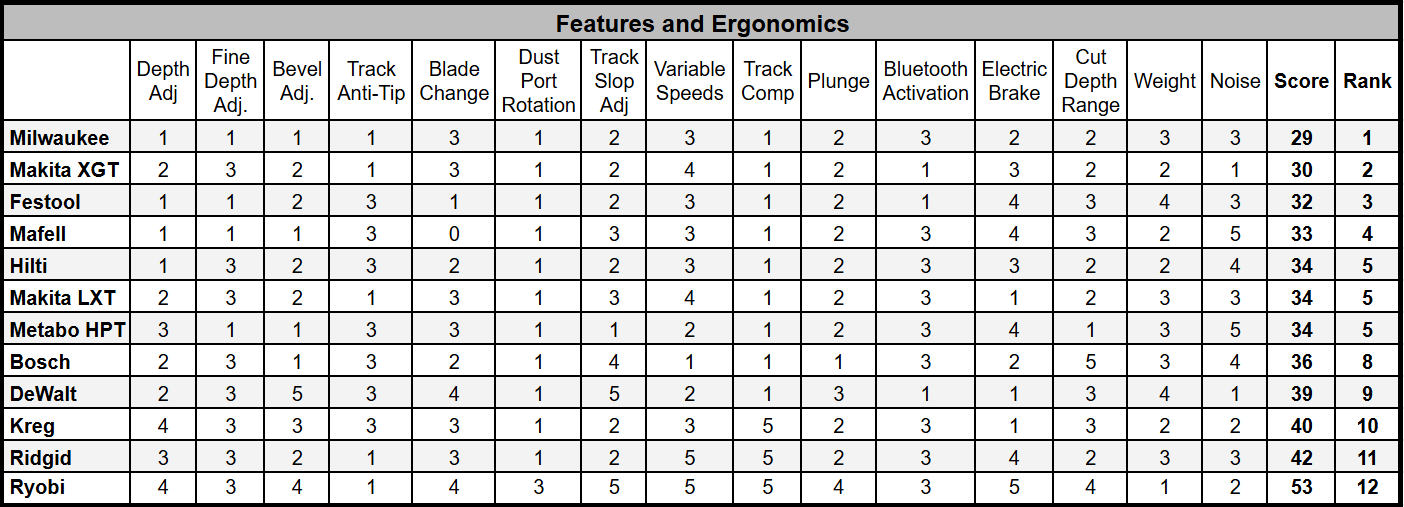

Track Saw | Features and Ergonomics – Winner Milwaukee

Track saws are feature-rich tools, and we evaluated 16 features to assess their performance across a range of criteria. Ergonomics plays a critical role in enhancing performance, reducing fatigue, and minimizing the risk of injury. In simple terms, it’s all about how the tool feels in the hand and how naturally it works with the user.

Each feature was rated on a scale from 1 to 5, with 1 being the highest rating. We focused on the following track saw features:

- Depth Adjustment

- Micro Adj.

- Bevel Adjustment

- Track Anti-Tip

- Plunge

- Blade Change

- Dust Port Rotation

- Track Slop Adj. [Guide Rail]

- Variable Speeds

- Track Compatibility

- Bluetooth Connectivity for Vacuum

- Electric Brake

- Scoring Cut Feature

- Cut Depth Range

- Anti-kickback

- Decibels

The Milwaukee track saw excels in features with a clean and easy-to-use depth adjustment and bevel adjustment. It has anti-tip prevention, offers track compatibility, easy and precise guide rail adjustment, a smooth plunging action, an electric brake, and a respectable cut-depth range. These top scores earned it a top score. [29-points]

Right behind the Milwaukee was the Makita XGT 40V track saw [30-points], which stood out for its anti-tip feature, rotating dust port, track compatibility, and Bluetooth activation. It also performed well in depth adjustment, bevel adjustment, track-slop adjustment, plunging, and cut-depth range. Festool came in at 32 points, excelling in depth adjustment, blade changes, rotating dust port design, track compatibility, and Bluetooth activation. It also placed second in bevel adjustment, track-slop adjustment, and plunging performance.

The depth-of-cut scale is also well executed, with clear indicators for cutting with or without the track, plus the inclusion of an imperial scale. Overall, Festool’s setup is one of the easiest to use, thanks to a smooth side-mounted spring and an excellent micro-adjustment mechanism.

One key takeaway from the team is that many of the features highlighted in this test—particularly track refinement, blade and plunge mechanics, and dust management—have been part of Festool’s system for a long time. Milwaukee and Makita have clearly made major strides, but in many ways, they are emulating innovations Festool pioneered years ago.

Breakout Details on Features

Depth-of-Cut | Micro-Adjust

Almost all of these saws offer a micro adjustment on the depth of cut for precise tuning.

Festool’s micro-adjustment for depth works via a small, dedicated adjustment screw or dial located near the depth stop lever, allowing for tiny increments of movement after the main depth is set, typically used to “sneak up” on the perfect depth by making test cuts and fine-tuning in very small steps. Like the rest of the saws, this is a trial-and-error process for precision, where exact depth is critical, using the screw to move the depth stop up or down just a hair until the blade depth perfectly matches the workpiece thickness or desired reveal.

Metabo’s front-situated adjustment is also a strong design, as it’s easy to see, reach, and operate. Mafell and Hilti offer positive detents for adjustments.

Milwaukee places its adjustment low on the tool, which makes it less convenient and harder to access during use. Mafell and Hilti both use finer detents that allow for very precise depth settings, but their systems are not quite as intuitive or user-friendly as Festool’s approach.

Plunge Mechanism | Action

Bosch and DEWALT both use torsion-style plunge mechanisms, but when compared, they feel very different in use.

The Bosch has a lower strength axial-plunge spring and is NOT as strong as the others, but the result is a super easy, and ultra smooth plunge action.

The DEWALT also has a parallel linkage plunge mechanism that requires the user to push the saw carriage forward slightly on the base before plunging it down at an angle. All of us agreed it is an awkward movement, because the other saws pivot down into their bases with one wrist motion.

Overall, the team was not a fan of this plunge mechanism. Festool, Mafell, and Makita all have robust, linear compression-plunge springs and are all on par with ease of plunging. The remaining saws rely on a more conventional spring-and-pivot-point design for their plunge mechanisms. The Milwaukee M18 stood out with the strongest plunge feel, driven by a very stiff spring.

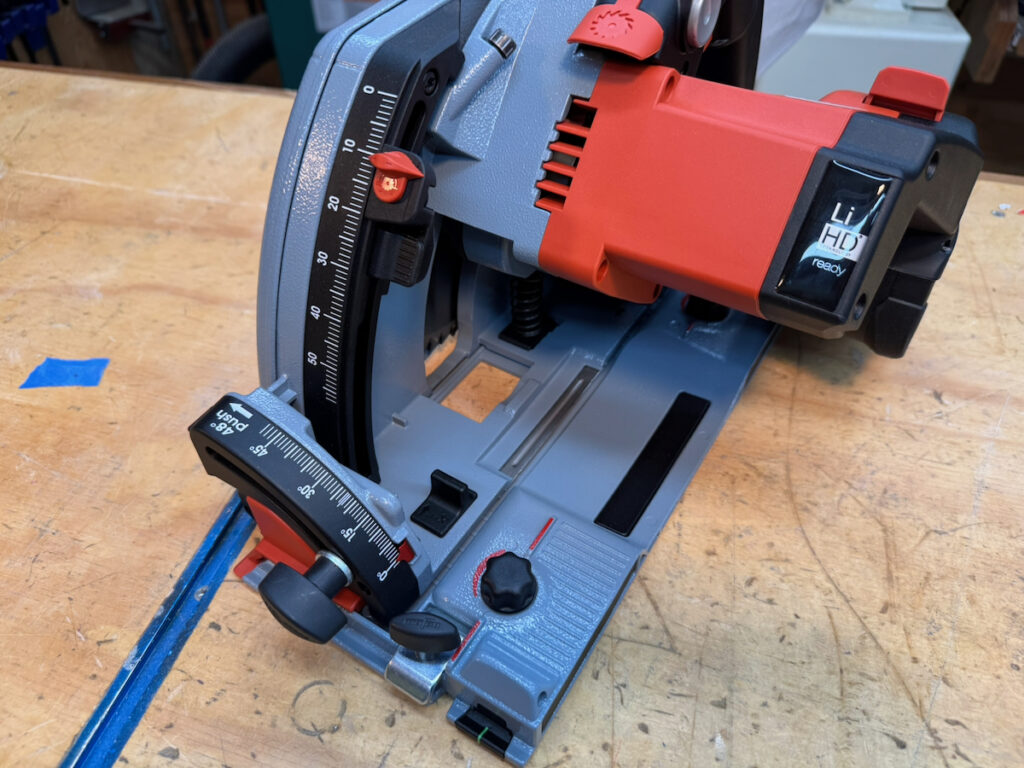

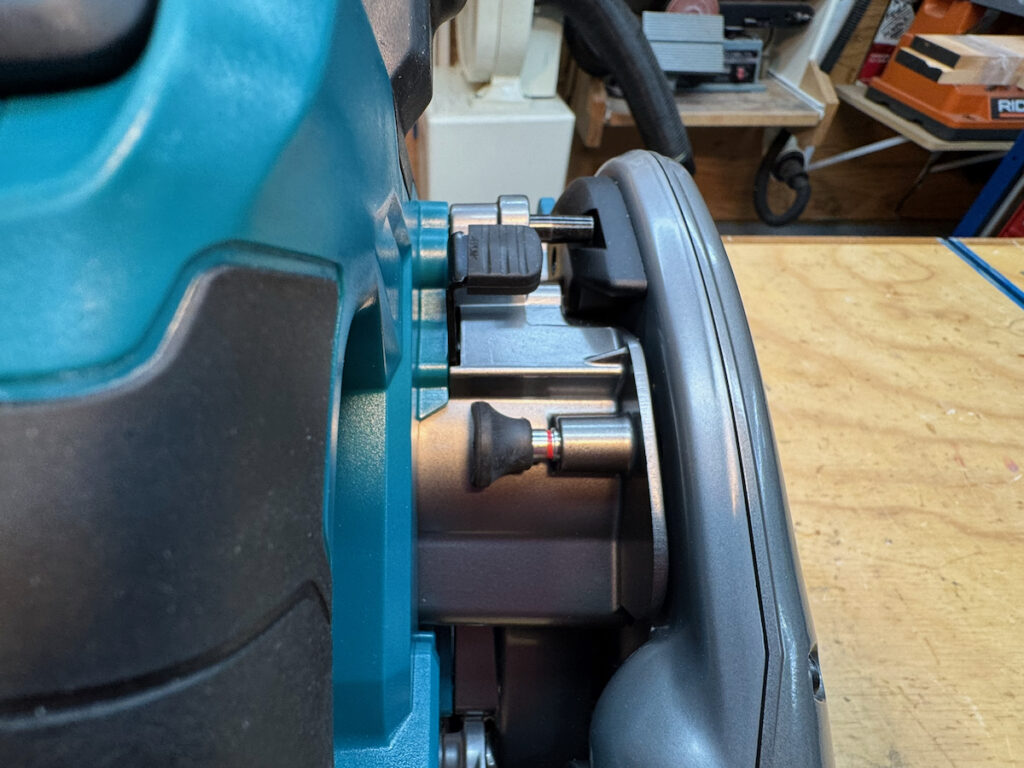

Bevel Adjustment

All but one saw in this group used two knobs or controls to unlock and adjust the bevel. The execution, however, varies a lot from brand to brand—and some systems are far better thought out than others. Most track saws in this group rely on two knobs or controls to unlock and adjust the bevel, but the quality of execution varies significantly from brand to brand, with some systems far more refined than others.

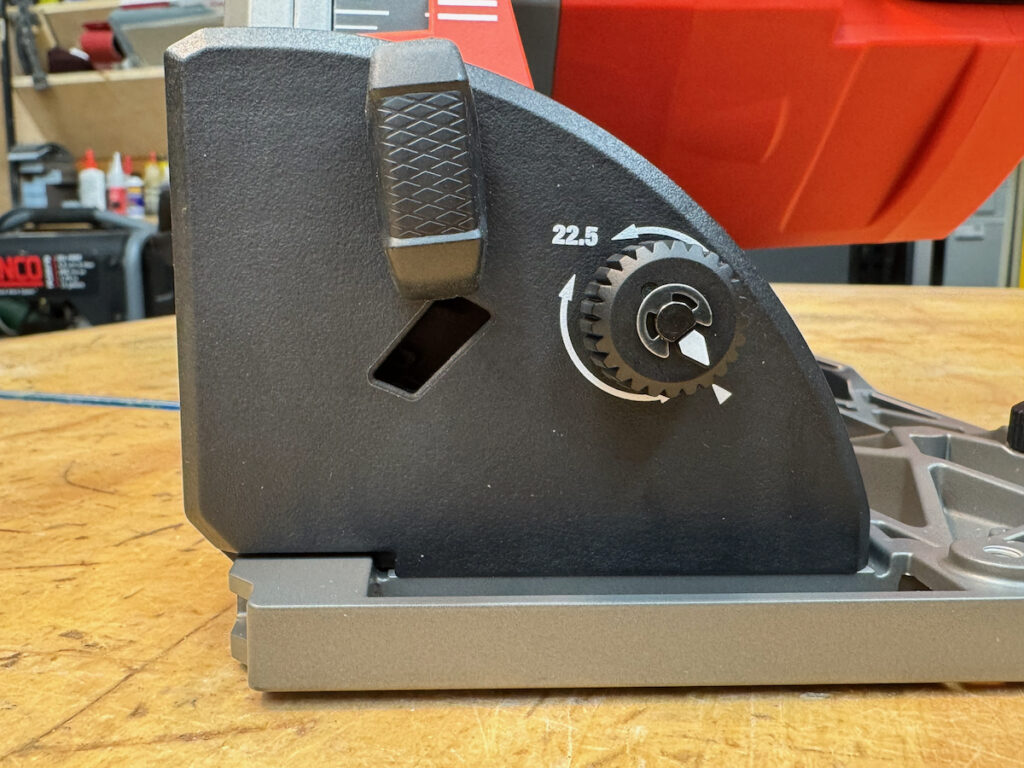

Milwaukee uses a one-button system to access the negative bevel down to -1°, along with knobs for the 22.5° setting. The system is functional and decent, but it doesn’t really stand out.

Mafell delivers one of the most intuitive bevel systems overall, using a single upright button for standard beveling and two clearly marked front-mounted buttons to engage the -1° and 48° bevels. Everything is easy to see and operate, and the saw is engineered so bevel cuts don’t damage the anti-splinter strip, which is a major advantage.

Festool uses front and rear locking bevel knobs and bevels from -1° to 47°, with the negative bevel control located up front at the dial indicator and the over-bevel release positioned at the rear under the dust port. Its lever-style push/pull system is very easy to use, though it does not include 22.5° or 25° positive stops.

Makita bevels from -1° to 48° and includes a solid 22.5° positive stop, using a rocker switch for the 48° bevel and a small slide switch for the -1° setting. The addition of an anti-tip feature makes bevel adjustments smoother and more confidence-inspiring, resulting in a well-rounded system.

Bosch’s fit and finish feel a bit rougher than some competitors, but its bevel system is refreshingly simple, relying on a single push-button control to bevel from -1° to 47°, which the team found straightforward to use. DeWalt bevels from 0° only, limiting its versatility. Ridgid uses a two-button setup with a 22.5° detent that works adequately, though it feels more basic compared to premium brands. Hilti, Kreg, and Ryobi are more limited overall, lacking negative bevel capability and offering less refined controls and fewer reliable positive stops, which makes them less suitable for precision bevel work.

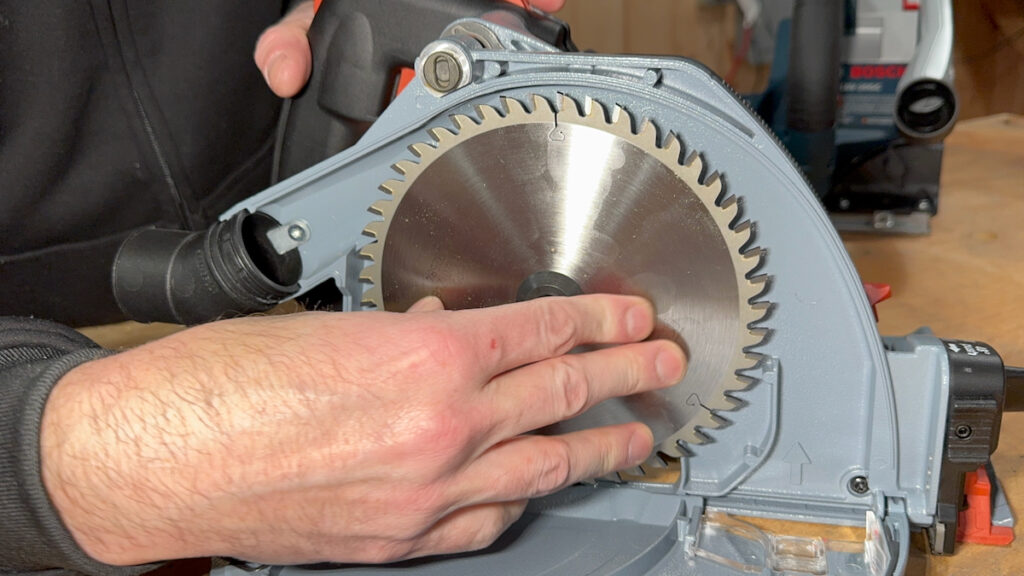

Blade Change

Blade-change design plays a big role in day-to-day usability, and the differences between these track saws range from exceptionally well thought out to unnecessarily complicated.

Mafell offers a highly refined system with a single button that both locks the arbor and opens the blade-guard door, which is hinged at the bottom. This design allows the blade to be changed with the saw resting flat on a table, without needing to plunge the saw, and the wrench is conveniently stored at the rear of the tool.

Festool’s Fast-Fix system is one of the simplest to use: lifting the lever on the handle and plunging the saw automatically locks the arbor, making blade changes quick and intuitive, with the wrench stored directly under the Fast-Fix lever.

Bosch’s process is similar to Festool’s but requires the user to manually hold the arbor lock button while changing the blade. The wrench is stored on the saw base and is both easy to access and more secure than Makita’s storage. Milwaukee’s process is super easy as well.

Metabo HPT’s process is over complicated and similar to the Ryobi; both have a hard-to-reach spindle lock. Metabo’s arbor locking feature helped its score in this category, but it needs to make this process easier. Makita’s blade change requires rotating a teal-colored depth-lock knob and plunging the saw to lock the blade, while also holding the arbor lock during the swap; the wrench is stored on the bottom rear of the saw housing.

DEWALT has the most cumbersome blade-change process of the group, requiring multiple steps that include pushing and rotating the spindle lock, plunging the saw, and holding the lock while rotating the blade into position, making it the least user-friendly system we tested.

Anti-Tip Feature

Makita, Milwaukee, Ridgid, and Ryobi all include integrated anti-tip features. Makita and Milwaukee stand out because their tracks use a slot along the side of the top T-track to engage the anti-tip mechanism, allowing the anti-tip systems on both saws to work interchangeably on each other’s tracks. Ridgid and Ryobi, by contrast, use proprietary track designs. Festool and other compatible tracks do not support an integrated anti-tip feature.

Anti-kickback Protections | Riving Knife

Rather than using a mechanical riving knife, some of these saws incorporate electronic safety systems. Others simply omit the feature and depend on operator control and cutting technique. A riving knife isn’t the only line of defense against kickback; its absence means the saw relies more heavily on electronics—or the user—to manage that risk.

Bosch offers a Vari-Torque clutch, which allows the blade to slip when it encounters resistance, thereby reducing kickback. Festool, on the other hand, has a metal “feeler-wedge” trigger located at the rear of the saw. This wedge, which resembles a riving knife, activates to stop the saw’s blade when engaged. There’s also a button on the saw that can override this feature for certain cutting operations, particularly on uneven surfaces or off-track cuts.

Mafell provides an electronic feature that continuously monitors the blade’s speed, instantly shutting it down if it senses binding. This mechanism is faster than traditional spring-loaded systems.

In this group, riving knife usage is clearly divided.

Saws With a Riving Knife

Ryobi

DEWALT

Kreg

Ridgid

Milwaukee

These saws rely on a traditional mechanical riving knife to manage blade pinch and help prevent kickback.

Saws Without a Riving Knife

Mafell

Hitachi

Festool

Makita (both models tested)

Metabo

Bosch

Track Connection & Alignment

Track connection and alignment performance varies widely across brands, with Bosch, Mafell, and Metabo HPT scoring the highest. These saws use a single-piece connector that aligns tracks exceptionally well, can be secured with a slotted screwdriver or coin, and allows unobstructed clamp travel along the underside of the track.

Festool also uses a well-machined single-piece connector with two set screws per track, and both Festool and Makita allow the use of dual connectors to further improve alignment consistency. DEWALT tracks, by contrast, were difficult to align due to play between the connector and the extrusion, reinforcing the recommendation to use full-length rails.

Metabo HPT features a wide engagement plate with a smooth fit, easy installation, minimal slippage at the cut edge, and lateral adjustment capability, earning it the highest connection performance ranking.

Hilti uses a single bottom joining rod with a slotted screw, providing very smooth engagement with minimal interference from the track lip. Milwaukee relies on solid top and bottom rails for adjustment, which are simple and secure once set.

Kreg employs a multi-piece joining system similar to Makita’s; it operates smoothly but produces audible feedback when sliding over the track lip and has limited compatibility.

Ridgid uses bottom-mounted joining rods with a rubber interface, which work smoothly but are not compatible with other track systems. Ryobi’s track tends to catch at joints, particularly in cold conditions, requiring the back plate to be loosened to pass the joint, which introduces “slop” and reduces alignment accuracy.

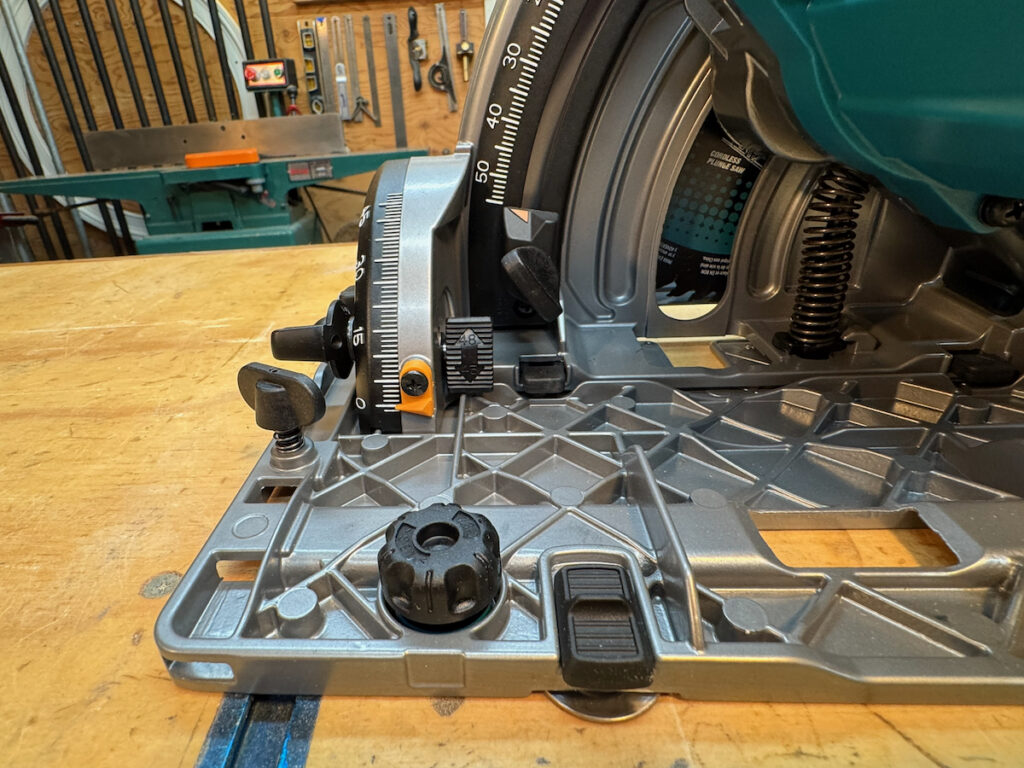

Guide-Rail Adjustment | “Saw-Slop” On Track

All of the saws have some sort of guide-rail adjustment mechanism to ensure the saw has a smooth gliding action and to prevent side-to-side movement during cutting.

The Metabo HPT saw WOW’d the team with its “one-and-done,” single adjustment knob that engages a cam mechanism and coupling rod that adjusts the saw’s base plate to remove play and ensure a snug fit on the guide rail. Bosch’s adjustment mechanism, however, is too easy to move and can be inadvertently knocked out of position or “over-shoot” your desired setting.

DEWALT required a screwdriver to unlock adjustments, but once set, the settings remain stable.

Festool relies on cam-style knobs that push against a replaceable plastic bar; while slightly harder to reach, they hold adjustments securely. Mafell features a dial with detents that provides precise and repeatable settings.

On Festool, Hilti, Mafell, Makita LXT, and the Metabo HPT, saws, battery placement—particularly with larger battery packs—can partially obstruct access to the rear adjustment controls. They all use large, easy-to-turn knobs with a stiff, confidence-inspiring feel.

Variable Speed

Variable speed control is essential when switching between different materials, allowing the saw to be matched to the material for optimal cut quality and control.

The Bosch saw features variable speed control integrated into its illuminated user interface. It includes a push button that allows you to select from six customizable variable speed RPM settings, [accessed through the Bosch App], plus an ECO mode that extends battery runtime by up to 30%.

The Metabo HPT track saw, on the other hand, has a variable speed dial with 12 settings, allowing you to adjust the blade’s RPM range from 2,500 to 5,200 RPMs.

Blue-Tooth Compatibility

Many of these saws offer Bluetooth-enabled apps that integrate with batteries and accessories, but the clear standouts in this comparison were the DeWalt 60V, Festool, and Makita 40V saws due to their ability to automatically control proprietary dust extractors.

DEWALT’s Wireless Tool Synchronization (WTS), part of the Tool Connect system, uses Bluetooth to start and stop a linked DeWALT dust extractor when the saw is activated, with a brief run-on to clear residual dust, while also enabling app-based features such as tool management, usage alerts, and remote disabling.

The Festool TSC 55 KEB offers Bluetooth vacuum control [through specific enabled batteries] that automatically turns a compatible Festool dust extractor on and off with the trigger, improving dust collection and eliminating manual vacuum operation.

Makita’s Auto-Start Wireless System (AWS) similarly provides wireless power-on and power-off with AWS-equipped dust extractors, reducing noise, extending cordless vacuum runtime, and improving workflow; the system uses a small transmitter installed in the tool and can also work with corded extractors via Makita’s AWS Universal Adapter.

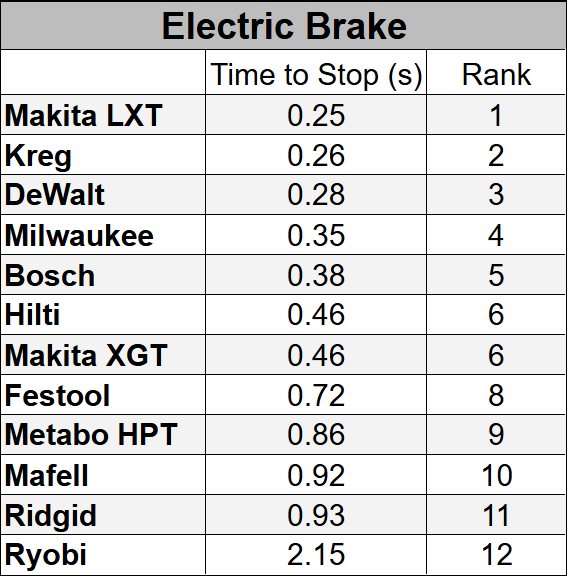

Electric Brake

We timed the electric brakes on the saws. All of the saws were under one second, with the exception of the Ryobi, which was 2.15 sec.

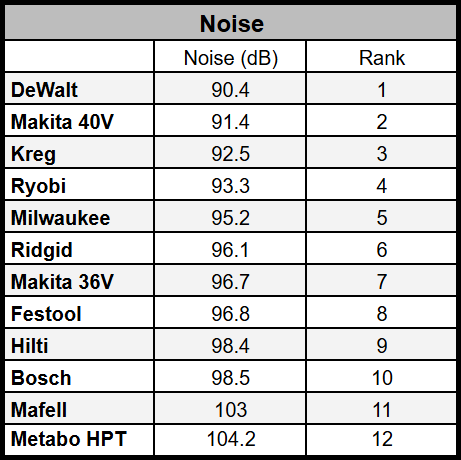

Decibels | Winner Dewalt

A few track saws clearly stand out as the quietest in the group.

DeWalt takes the top spot with a noise level of 90.4 dB, making it the quietest saw tested. This gives it a noticeable advantage for indoor work or job sites where noise matters.

Close behind is the Makita 40V, measuring 91.4 dB. Its low noise output, combined with Makita’s reputation for smooth operation, for users who want power without excessive sound.

The Kreg track saw ranks third at 92.5 dB, still comfortably within the quieter end of the field. This puts it ahead of many premium competitors and makes it a solid option for DIYers and professionals alike who value a quieter cutting experience.

Rounding out the top four is Ryobi at 93.3 dB. While slightly louder than the top three, it remains relatively quiet compared to the majority of the saws tested, offering good noise control at a more budget-friendly level.

We also noticed that the Bosch track saw, while not the loudest overall, had a noticeably high-pitched, piercing tone. This higher frequency sound made it subjectively more unpleasant to use compared to other saws, even those with higher measured decibel levels. In real-world use, tone and pitch can matter just as much as volume, and the Bosch’s sharper sound stood out as the most fatiguing and least comfortable to the ear during cutting.

Adjustments and Switches

The Bosch interface is an illuminated user interface that provides clear, at-a-glance control and feedback. It offers a push button to select six variable speed settings, and an ECO mode to extend battery runtime by up to 30 percent.

Its stoplight-style battery indicator shows remaining charge, while a temperature and overload light warns of overheating or excessive load. The saw is also connected-ready; with the optional Bosch Connectivity Module installed, a Bluetooth indicator enables connection to the Bosch PRO360 or Bosch Toolbox app for added customization and feedback.

The Mafell was the clear standout in this category. Its single bevel adjustment knob, combined with a push-button and lever blade-change system that also locks the arbor, makes setup intuitive and adjustments quick and easy. It also features a dedicated surface on the front corner of the base plate, opposite the blade, where the user can apply thumb pressure to help prevent the saw from tipping during bevel cuts—a nice ergonomic touch.

Festool’s buttons and interfaces are almost all in a high-contrast bright green, allowing you to laser focus on the adjustment knobs. The Festool adjustments have a good feel to them and there’s no slop in knobs, buttons, and levers. With little time with this saw it becomes exceedingly easy to use and adjust, and only requires an onboard Allen key for blade changing.

Makita’s controls are also easy to use. The “blade-down” lock is not as intuitive and requires two hands to engage. The user then needs to press the arbor lock. Most of the adjustments are easily figured out by where they are and how they interface with the saw. However, the tolerances feel a little looser than the Mafell and Festool.

The team’s primary concern with the Ryobi saw was the left-side safety switch (for right-hand-dominant users). Several users found the switch uncomfortable and somewhat difficult to actuate. A more ambidextrous design with a push-down style button could improve overall usability.

Dust Ports

Almost all of the saws have an offset dust port for either a dust bag or a vacuum connection.

The team noted that Festool and Ridgid both offer the ability to rotate the port. Bosch, Kreg, Mafell, and Makita feature positive click stops, with the Makita XGT standing out in that group.

Metabo’s port pulls out to allow rotation, then pushes back in to lock—another really nice feature. DeWalt, Hilti, and the Makita LXT ports spin freely but generally hold their position well unless the hose tugs on them. Ryobi offers a fixed-position port that points straight out the rear of the saw.

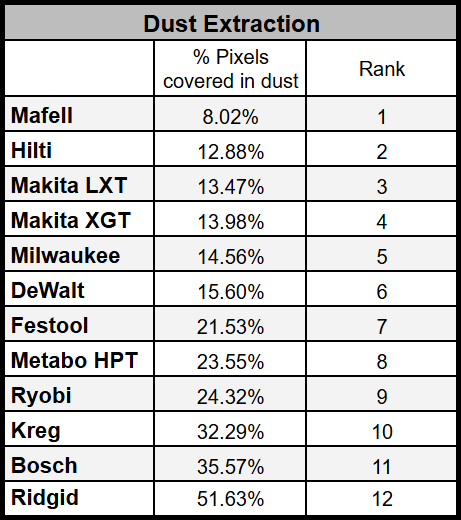

Dust Collection | Winner – Mafell

While most track saws perform better with a vacuum attached than a standard circular saw, the consistency and amount of dust collected vary significantly by manufacturer.

To evaluate the dust-collection performance of each track saw, we placed a blackboard beneath every cut to capture any debris that was not collected. After each cut, the board was photographed, and the image was analyzed to quantify the amount of dust left behind by the dust-extraction system.

Each image was first converted to grayscale to simplify comparison, then contrast was enhanced to make dust particles stand out more clearly from the background.

Because lighting introduced some glare in every image, we applied a background-suppression algorithm that identified large clusters of light gray or white pixels—defined as continuous areas larger than 200 pixels—and classified them as background rather than dust. These background areas were then converted to black.

With the images pre-processed, a fixed threshold value of 50 was applied across all samples (where 0 represents black, 255 represents white, and values in between are shades of gray). Pixels darker than the threshold were classified as background, while pixels lighter than the threshold were classified as dust. The percentage of white pixels in each image was then calculated and used to rank the saws based on dust left behind.

Note: All of the saws tested include dust bags and offer vacuum connectivity. While finding the correct vacuum attachment can sometimes be a challenge, we believe most users will connect their saw to a vacuum whenever possible, as we did for this test.

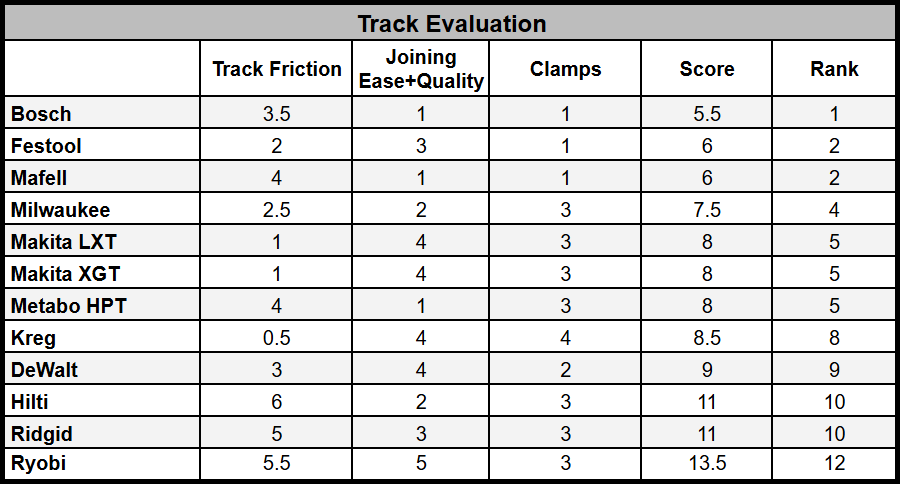

Guide Rail | Track Evaluation | Winner – Bosch

When comparing tracks, we looked at the following 3 features:

Anti-Slip Performance

Many track saw users will often cut materials without clamping the track down, and in some situations, you can’t clamp. We decided to evaluate the anti-slip performance of each track.

Jointing and Connectors

This evaluation focuses on how easily multiple track sections can be lengthened and aligned, and how well they maintain alignment under load. We considered ease of joining, the alignment, and the smoothness of the seams at the joint.

Clamping Options

Clamping was evaluated based on ease of access, holding strength, and whether the clamps interfered with the saw motor or dust port during operation. We also examined the presence and design of underside grooves and their compatibility with manufacturer and third-party clamps.

Results

We preferred the Bosch / Mafell track overall. The Bosch and Mafell tracks are nearly identical, sharing the same “top-mounted,” wide, track connector, interchangeable anti-splinter strip, and grip strip parts. The Bosch / Mafell track is narrower, lighter, and thinner than the Festool track, and once joined, offers little to no “lippage” at the joint.

The anti-splinter strip and grip strips for the Mafell style fit seamlessly into the track without the need for adhesive, which makes them easy to replace when worn out and prevents them from flapping around at the end of the track over time.

There are a couple of drawbacks to the Bosch / Mafell track. One is the absence of a T-slot on top of the track, and the other is that the narrow width causes the base of the saw to cover the entire width of the track.

However, the Bosch / Mafell clamps fit fully into the bottom of the track in two locations (one of which is very close to the cut) and do not interfere with the track connectors, allowing them to move smoothly along the full length of the track without obstruction.

Bosch also had the easiest to use pistol-style clamps – These clamps feature an ergonomic pistol-grip handle that provides a comfortable, firm grip, allowing users to apply enough pressure to ensure the saw is securely fastened to the track.

The Kreg track has a 4-piece joining rod system. Installing these rods requires precise alignment and can result in user frustration. Once joined, we notice some “lippage” on the cut side of the rail.

The Festool track profile has always been excellent. It is a reference standard and widely copied. Bosch, DEWALT, Hilti, Makita, Mafell, Metabo HPT, and Makita saws can all run on Festool tracks.

The Festool system uses two different, non-interchangeable connectors—one for the top and one for the bottom of the guide rail—to achieve consistent alignment, which can frustrate some users. Once joined, the track showed minimal “lippage.”

The Festool system uses two different, non-interchangeable connectors—one for the top and one for the bottom of the guide rail—to achieve consistent alignment, which can frustrate some users. Once joined, the track showed minimal “lippage.”

Festool uses glued-on, replaceable anti-splinter and grip strips. Over time, the ends of these strips can loosen, which may affect saw setup accuracy.

Makita has a 4-piece joining rod system – one for the top and one for the bottom of the guide rail. Installing these rods requires precise alignment and can result in user frustration. Similar to the Festool, once the rods are in place, we recommend you store them on the guide rail to avoid future frustration. We also noticed some “lippage” on the cut side of the rail.

Milwaukee uses two solid joining rods, secured with Allen screws, positioned on the top and bottom of the guide rail. Both rails are identical, requiring no specific alignment, and there is minimal to no “lippage” at the track joint.

Ridgid and Ryobi assemble well, but we noticed that the saws tend to catch slightly at the joint where the top black strip ends on one track and begins on the other. To prevent this, you’ll need to loosen the saw’s alignment on the guide rail, which results in more side-to-side play than our team would prefer.

Best Cordless Track Saw | Winner – Mafell

The Best Cordless Track Saw is the Mafell cordless track saw. It excelled in almost every category, resulting in a score of 20 points

The Mafell MT 55 CC track saw is known for its precision, smooth operation, and ease of use, and our testing showed that.

It delivers clean, straight cuts on its solidly designed guide rail. It’s a feature-rich tool with notable features like its quick and accurate depth adjustment, amazingly simple blade change, and soft start motor. The only category it didn’t excel in was features, but the features it did have are excellent. Overall, it’s a reliable, durable tool built for accuracy and efficiency.

The Festool TS 55 K track saw is known for its precision and clean cuts, with a solid track system. The depth adjustment is quick and stays locked, and the motor is powerful yet smooth, with no jerky starts. Its dust extraction system is excellent. The saw is lightweight, well-balanced, and comfortable to handle. It suffered a bit on dust collection, which hurt its overall score. Overall, it’s a reliable and efficient tool for carpenters who need accuracy and power in their work.

The Makita GPS01Z 40V Max Track Saw is a cordless option that offers solid power and convenience. It provides clean, accurate cuts with a reliable guide rail system. The depth adjustment is OK, but it stays locked in place. It offers decent features, power, and dust collection.

It basically scored 4 or 5 in almost every category except precision.

The Milwaukee M18 Fuel The Milwaukee M18 Fuel 2831-20 is a relatively newer cordless track saw to the market, and they obviously had time to make it a good one.

The M18 saw offers excellent cutting speed, power, and performance. The saw delivers clean, straight cuts with a solid guide rail system. It is feature-rich, well-balanced,

Overall, it’s a reliable, cordless option for those who need flexibility and solid cutting performance without being tied to a cord.

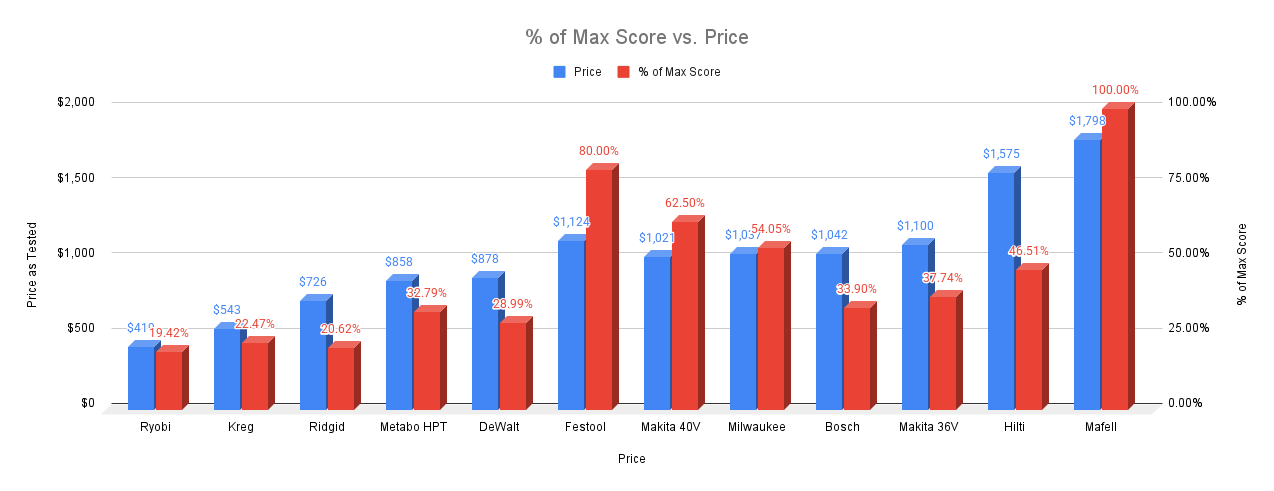

Price vs Performance – Value Comparison | Winner – Festool

Some brands deliver excellent performance but at a higher cost, while others offer great value for the price. We compared the cost versus performance to highlight the best values in this category. This is a new approach for us, which is kind of fun, as we try to quantify things a bit more.

Our value chart shows the percentage of the best score, which belongs to the Festool, marked in red at 100%, compared to the prices of all the other Track Saws in the category. Ideally, you want a high red bar (performance) and a low blue bar (price).

The Festool took 2nd place overall and comes in for $1,124.00, as shown by the red bar almost reaching the top. It’s a great performer, but it’s also one of the more expensive options.

We’d also like to point out that you can get into a decent-performing Track Saw at a great price. Take a look at the Kreg. At $543, this saw came in 10th place, which is almost $220 less than the Ridgid and $300 less than the Metabo HPT, providing excellent value for the price.

Which Track Saw Should You Buy?

Choosing the right track saw comes down to your specific needs, priorities, and budget. While we’ve named our overall pick, we’ve shared all the test data so you can weigh the factors that matter most to you. With this information, you’ll be equipped to make a confident, informed decision and choose the cordless track saw that best fits your work.

Best Track Saw | Conclusion

Our pro contractor team invested extensive hands-on time to deliver one of the most thorough head-to-head track saw evaluations available. While we’re not a formal testing lab and can’t replicate long-term durability testing or every possible use case, each test was carefully executed and closely analyzed. Every saw in this review is a solid option, and our results clearly highlight where each one excels and where it falls short—helping you decide which saw is the best fit for your needs.

Best Cordless TrackSaw Head-2-Head Video

Leave a Reply

You must be logged in to post a comment.