Making A Box Joint Jig

How to Make A Box Joint Jig

A box joint’s exposed end grain can be an attractive detail. Box joints are a simple, economic way to produce a strong joint. They can be built on the table saw with a simple jig made from remnants from your scrap pile.

A box joint jig is not a new idea. It has been around for a long time and a simple plan to build one can be found on the Internet.

Common box joint spacing dimensions are ¼, 3/8 and ½-inch. Box joints look and work best when the width of the joint is divisible by the width of the individual joint fingers.

Making A Box Joint Jig Steps:

The material for the box jig fence is ¾-inch plywood because of its strength and resistance to warping, but any solid, straight lumber will work.

Instead us using the table saw miter gauge I decided to make a sliding sled. When making A box joint jig sure the rails of the sled extend beyond the blade a few inches on either side to support the sled when sliding.

Photo: Sliding rials were cut to fit snug in the slots in the table saw.

Take care to keep the sled, rails and fence square with the blade.

Rails were attached to the bottom of sled with recessed screws. Later I applied paste wax to assist it slide.

The operator side of this sliding jig is at least six inches tall to keep my fingers away from the blade and support the work piece adequately. I also made the width of the sled approximately 18 inches, for safety and to support larger pieces.

Cut material for the indexing pin and spacer “stick.” Take care to get the thickness exactly right. I have found it easiest to rip a piece slightly oversize, then plane or sand it to the correct dimension.

A dado was cut into the fence to receive the index pix. The index pin was then glued and screwed into the fence support. The spacing between the pin and the blade is exactly the width of the pin. I used scrap pin material as a spacer.

I set the dado blade height to just over ¾-inch, the thickness of the stock being machined. If you are using thicker or thinner stock, blade height and the height of the indexing pin will have to be adjusted accordingly.

Setting the blade a little high for the material being used cuts 90-degree fingers that protrude slightly when assembled. It is much easier to sand the pins flush than shave down the sides of a project. Start the saw and carefully pass the jig over the blade to make the initial cut.

There are a few ways too start the pin cutting so two sides will interlock. One way is to hold the piece, to be cut first, tight to the index pin, the second piece is then spaced away from the pin with a spacer. This method is shown below for easy of photo viewing.

Another way is to cut both pieces at the same time, spacing one off the pin. [similar to below]

Spacing the second piece can be accomplished buy using scrap wood, with a dado cut in it, as a spacer. This allows the second piece to be spaced away from the index pin, which allows both pieces to have opposite cuts and interlock together.

After the spacer is removed the cut fits onto the index pin.

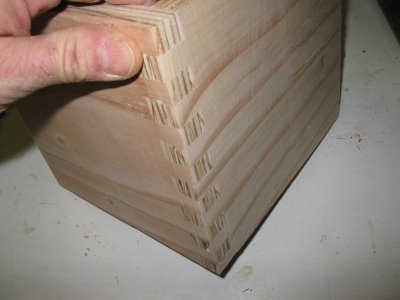

The fingers of a box joint are called “pins” and the notches are called “sockets” The box joint lacks the mechanical locking of the dovetail joint. It derives it’s strength from the glue. The glue must be spread evenly on all mating surfaces.

Box joints add a professional touch to your projects, generally the thickness of the material and the width of the tails are the same, they should be cut slightly deeper then trimmed for a perfectly flush fit.

After trimming or sanding. Now…. what should I make with this?