Measuring Tools for the Workshop

Measuring Tools -That DON’T break the Budget

Measuring and layout mistakes can be time-consuming and costly. Learning the hard way how to measure properly is not fun. Measuring properly involves attention to detail, good judgement and experience.

Story Pole

Over the years, I’ve developed strategies to measure and layout parts to achieve accurate work and avoiding mistakes. Such as:

I’ve also compiled several layout tools that help me achieve success. This article is about those tools.

Repetitive cut jig – 6″ plinths

Measuring Tools for the Workshop

Measuring is the first step in wood-working, marking is the second step. If done properly you should be on your way to accurate assembly work.

We all have heard the carpentry golden rule: measure twice, cut once. In most workshops, this means using a tape measure to check and recheck the accuracy of a part’s dimensions before cutting to size. But what happens if that tape is old, bent, and out of calibration?

You should check this and make sure you have an accurate tape measure

One of the most critical tools required by all construction trades is the tape measure. So, who makes the best tape measure? Pro-grade tape measures must retain their accuracy while enduring the regular abuses, such as drops or bumps, that occur on job sites.

We evaluated 8 different tape measures from 7 different manufacturers, five of which had magnetic tips In this Best Tape Measure Head-2-Head, we put several 25’ premium tape measures to the test.

How much accuracy you need depends on the kind of woodworking that you do.

Here’s a secret; start out with high precision and stick with it all the way through.

To avoid measuring mistakes caused by using more than one measuring device — whether it’s a ruler plus a measuring tape, all your measuring tools have to agree. The way to do that is to have a set of high-quality measuring tools to you use as reference standards to test all the other measuring tools in your shop against.

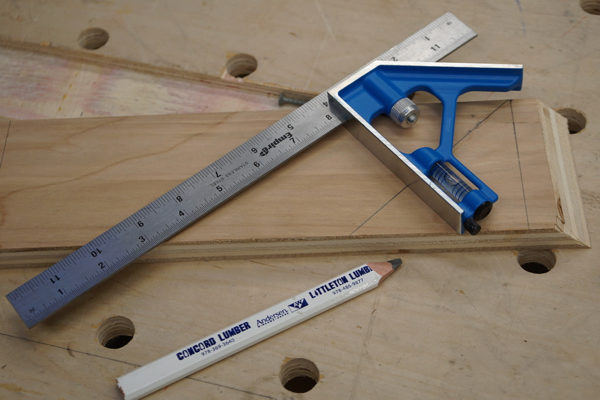

Combination Square

Combination squares are an essential measuring tool for any workshop, metalworking, or construction jobsite. Whether you are measuring angles, gauging depth, or finding the center on rounded objects, or checking 90° and 45° on any stock or tool, transferring dimensions, and finding centers

A good-quality combination square, such as this 6” Empire True Blue E250 Combination Square.

You want a tool with 4R graduations (meaning 1/8, 1/16, 1/32, and 1/64″) with etched markings that are easy to read (as opposed to stamped)

Besides being accurate, if you’re like me, you want a rugged tool that will last. Some woodworkers prefer the smaller 4” combination square for tight spots – I like both.

Stainless Steel Ruler

A stainless steel ruler is great for small parts. It not only helps you mark perfect measurements, but it also proves indispensable at setting blade and bit heights on machines, as well as checking the accuracy of measuring tapes.

Steel rulers can range from 6” to 72,” but the ones I use most often are 12” and 18.” If you can get only one such rule, we recommend a 12″ version.

Chose a ruler that has a dull finish (to diffuse shop lighting glare), etched markings, and scales in at least 1⁄8 ” and 1⁄16 ” increments. A1 ⁄32 ” scale is great for super accurate and I’ve found that a 1⁄64 ” scale is too difficult to read and mark.

In my shop I use an Empire Stainless steel ruler 27318-18.”

Digital Calipers

A quality digital or dial caliper is the only way to accurately measure board thicknesses as they come out of a planer or for checking widths when ripping boards on a table saw. They are also great for fine-tuning mortise and tenons.

In my shop I have an Empire Digital Caliper 2789-6.” It’s made from hardened stainless steel with satin chrome finish. 9 1⁄8” long and is accurate to .0005/.25mm. This caliper allows a 3-way measuring- inside, outside, depth and has an LCD display with automatic power off.

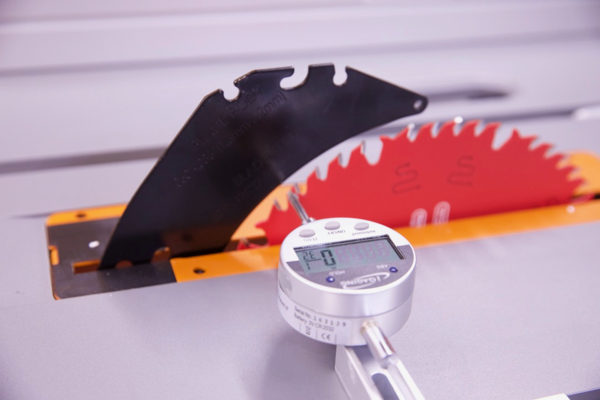

Dial Indicator

Often, a dial indicator and stand, magnetic holder or miter slot holder are the best tools to set up your table saw and fixed tools. Decent ones are not very expensive. A dial indicator and magnetic base, combined with calipers can help fine tuning table saw cuts, planer and sander thickness and tuning mortise and tenon joints. I use a iGauging 35-125-4 digital dial indicator.

Try Square

A try square is great for transferring lines and checking for square. It’s also

Useful to us to as a shop standard, for testing all your other measuring tools, and setting up your fixed power tools.

In my shop I use the Empire 122-8” Try Square, which is a stainless steel etched blade and heavy-duty aluminum billet handle. This try square has inch graduations and is durable and accurate.

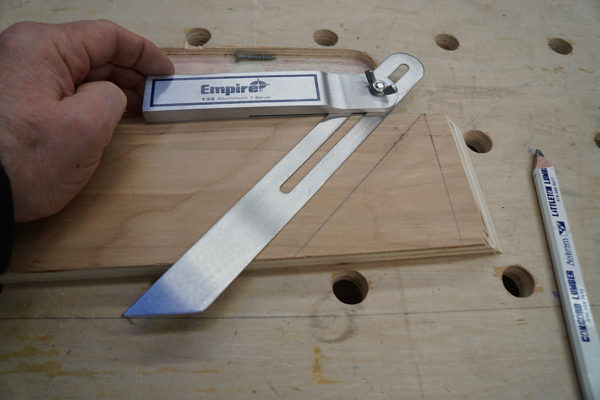

T-Bevel

A T-bevel is useful for laying out and transferring angles, and are ideal when 90° angles are not possible.

I use the Empire T-Bevel 132-10.” I like that it has a heavy duty aluminum billet handle, adjustable 10″ stainless steel blade for reaching across boards.

Carbide Scriber

A carbide scribe is indispensable when working with metal, and glass. As anyone who has marked metal will tell you, a pencil doesn’t work and neither do most pens. A carbide scribe uses a carbide tip to mark a clean sharp line through dirt, paint, rust, and mill scale.

Compass Scribe

I don’t use a compass in the shop often but when I need it, I really need it. I use an Empire Compass/Scriber 27031 which is ideal tool for scribing in addition to making circles. Made of a tough coated die-cast body, it also includes a hardened steel scriber pin.

Scribing is a simple technique that lets you fit cabinets, countertops, moldings and almost anything else to crooked walls.

“Avoid the One Step Forward, Two Steps Back!”

Measurement tools are often an afterthought when compiling tools for a workshop, but they shouldn’t be. A minuscule measurement error mistakes can be time-consuming and costly.

Taking the time to invest in measurement and layout tools, will ensure your layut and measuring projects are accurate!