Cost effective Multi-Tool Blade Blades:

What’s your biggest pet peeve with your multi-tool?

I bet it’s the cost of the replacement blades. Was I right?

The problem I have is coughing up the $27.00 for a new bi-metal blade every-time I start a job.

I recently came across a distributor of high quality replacement oscillating blades. The site is called Imperial Blades and they make a huge selection of blades from wood cutting high carbon steel to carbide and diamond marble cutting blades.

The prices are decent too!

I tried a few of their blades and ended up with a favorite:

T330 1-1/4″ Titanium coated, Bi-Metal 34mm blade:

This blade is a game changer, I was amazed at how well it cut and how long it lasted. It has 18 teeth per inch and the Titanium coated blade allows you to cut almost anything, from wood to nails or screws. This blade is still priced less that the Fein blades I’m used to buying. At $12.39 per blade it’s an absolute steal!

Imperial Blades coats the cutting edge of some blades with titanium nitride which increases the hardness, while it also greatly reduces friction.

How Do the Imperial Blades Cut?

I did not do any scientific testing I just used the blades in the field on differennt jobs side by side with my Fien blades. In my opinion they performed as well and in the case of the Titanium blades – better!!!!

Finding Imperial Blades online was a score for my construction business.

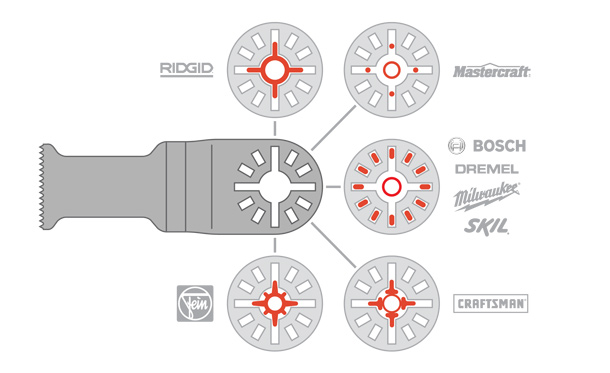

Do Their Blades Fit My tool?

Imperial blades makes replacement blades for oscillating tool by incorporating a Universal Blade Arbor. this arbor is designed to fits most tools requirements. The tools that fit the universal arbor are:

- Fein Multimaster

- Craftsman Multi Tool

- Dremel Multi Max

- Chicago Multi Tool

- Bosch Multi X

- Milwaukee Multi-Tool

- Ridgid Multi Tool

- MasterCraft Multi Tool

- Skil Multi Tool

Other blade arbors for Rockwell sonicrafter, Worx Sonicraft and Fein Supercut are also available.

Making Your Oscillating Blades Last:

Replacement blades for oscillating tools cost a ton of money – Most people tell me that the trick to an oscillating tools is to allow the weight of the tool to do the cutting and to use light pressure.

The better advice if to apply the correct pressure to the material your cutting and to apply blade movement. Most people push too hard on the tool and cause massive heat build up which prematurely dulls the blade.

CUTTING TIP – soap, wax or bees wax helps lubricate the blade and reduces friction which causes that nasty blade dulling heat.

Multi-tools vibrate and have a micro short stroke which by design do not remove waste from the blade kerf. If you rock the tool back and forth, pull the blade out of the kerf or cut along a line evenly as well as apply pressure the cut waste will find a way out. This keeps the kerf clean, the blade cooler and lessens the chance for you to burn your blade.