Hardie Siding and Trim Products

James Hardie Product Review

I recently dropped by Rob Robillard’s current project in Concord MA. to see it in person because I liked what I saw on social media. The large addition had been recently sided and painted. I asked Rob about the material because it looked fabulous. Rob told me it was sided with a James Hardie product – HardiePlank siding, a material he has used on several projects. Rob went on to say great things about the product look and durability. Rob’s endorsement made me curious to learn more about James Hardie products.

Interestingly, I saw a second example of James Hardie products. A nearby multi-building housing project in Dorchester, MA. began cladding their exterior walls with HardiePlank and HardieTrim Products.

I contacted James Hardie and they were more than happy to put me in touch with one of their local Alliance Partners. Shortly thereafter, I interviewed Jeff Brooks of Solid State Construction from Shirley, MA, about the James Hardie product line.

I wanted to know about James Hardie as a company. In addition, I wanted to find out how James Hardie’s product offerings fit into the market place. Jeff was very generous with his time and very helpful in taking me through the answers to my questions.

The Hardie History

The James Hardie Company began in 1888 when James Hardie immigrated to Australia from Linlithgow, Scotland, and created a business that imported oils and animal hides. James Hardie Industries Ltd first listed on the Australian Stock Exchange in 1951. For much of the twentieth century, James Hardie was the dominant manufacturer in Australia of a cementsheet and other related building products.

The company went through changes in the 1980s due to the asbestos content in their products. James Hardie engineered a way to use wood fibers within the composition of the Hardie product line as a substitute material. Today, HardiePlank and HardieTrim products are once again one of the World leaders in fiber-cement products.

Most James Hardie Siding and Trim products are currently fiber-cement based. The fiber-cement gives the offerings a durability that, if installed according to the manufacturer, will far out last the life of its wood, Masonite or vinyl competitors. The Hardie manufacturing process is quite fascinating and was the subject of a “How is it Made?” film that can be seen on social media.

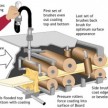

Lap Siding Manufacturing

While Hardie manufactures most of its products in a similar process to its Lap Siding, Hardie has some products like the Hardie Wrap that is made by a different process. In addition, Hardie has an extensive set of caulks and flashings that are color matched by other manufacturers to enhance the ease and quality of the final installations. These accessory products are carried by the network of Hardie product distributors.

The highlights of the film on the manufacturing process were:

- Consists of a composite of finely ground silica sand, wood fiber and bonding additives that are chemically bonded together in a manufacturing and curing process.

- Hardie products contain no asbestos mineral fibres.

- Available in a variety of factory applied colors.

- Siding has wood grained pattern or smooth finish into the silica/wood fibre slurry before the curing processes.

- From start to finish, the production process runs three days for the Plank Lap Siding.

The current Hardie manufactured product offering is shown in the figure, below:

The following two projects show the variety and use of Hardie products:

This apartment building in Dorchester, MA shows the installation of HardiePlank and Hardie Trim around the window lites.

The house project, above has a combination of HardiePlank siding, HardieTrim boards and battens.

Hardie On Top of Its Markets

While the current Hardie Siding and Trim Products offering is comprehensive, Hardie continues to look at what the market trend and demands call for in potential new offerings. Jeff is keeping his eye on James Hardie new product announcements and hopes to see shiplap and vertical batten coming soon.

During the interview with Jeff, I asked him what he or his customers might offer Hardie as constructive criticism of the product line. Jeff thought for a moment, then said,”

This is not much of a criticism, but sometimes customers remark that Hardie products look too good!”

Jeff went on to say that, the consistency and appearance of the Hardie products often stood out in stark contrast to other products and houses that were nearby. Jeff went further to say that he had very little to give me for an answer and that Hardie and their products were ‘doing it all right’.

During the course of the interview, I did hear one item that I would list as constructive to pass along to Hardie:

The relatively fixed number of factory-applied colors is limited to seven colors. Even this observation is not a showstopper because the installers can order James Hardie products with just a primer coat. Hardie products do take a coat of high quality house paints to provide any color the customer may desire. Jeff uses this type of primed finish if he needs to match an existing house color.

Is Hardie A Good Value?

So how does Hardie fit into the siding market place in terms of cost? The answer is that the Hardie products are situated in the mid-priced category for exterior wall finishes. Hardie is less expensive than brick or premium cedar wood siding. Hardie is often priced higher than finger jointed wooden clapboards or other man-made low end products.

Customers certainly recognize the James Hardie value proposition as the company recently announced that James Hardie products are now installed on over 8 million homes.

Comprehensive House Envelope Product Line

One of the interesting items in reviewing the cost is to look at the systems approach that Hardie promotes. When an installer completes the work, the caulking, flashing and sealing is entirely done and the house has a factory finished paint job (if so selected). Other exterior cladding systems will require substantial work to ready them for a finished coat of paint.

Hardie Supports Its Installers

One other item that Jeff mentioned in our interview is the close support that Hardie gives their certified installers. Not only does Hardie support their field crews with products, but also they assist with difficult or challenging technical issues that often arise on custom aspects of home reconstruction.

This following is a link to the James Hardie Pro Site that shows the James Hardie commitment to their Alliance Partners and a place to get started with James Hardie. The site is a real resource center for its partners and gives a wide variety of items. The site contains a diverse set of articles and topics ranging from outlining the compliance process and instructions to meet OSHA silica standards to the latest product information/news to setting a project’s HardieZone, This site feature matches the right James Hardie products that match your locations’ specific wet, freezing, heat, humidity and sun conditions. You can learn more at James Hardie Pros.Check it out because it is full of great information.

My interview led me to the conclusion that the James Hardie products line is an excellent value and with new products on the horizon, getting even better. This is a company that fully supports its customers and partners. James Hardie is a company that does it all the right way!