Factory Finished Siding

Using Factory Finished Siding and Pre-Primed Siding:

Most people think of using factory finished siding when they are considering using cement board siding. In my neck of the woods most of the homes are wood clad and I end up using alot of cedar clapboards and shingles for siding these homes.

I’m a big fan of using factory finished siding mostly because it ensures that the primer and first coat of paint is applied properly and under perfect environmentally controlled conditions. Because the primer and paint are applied at the factory you are ensured maximum durability on your paint job and superior adhesion. When a painter finishes your un finished siding on your house you have to hope that he prepares the siding properly, uses the proper primer, does not paint in the sun or when the siding is too wet, etc.

Using factory finished siding also cuts down on painting labor because it requires only a finish coat after installation.

When considering using a factory finished siding for cedar siding its best to choose a vertical or edge grain over a flat-grain species when used as an exterior siding. Vertical grain siding holds paint better, is less likely to check and has better longevity. While natures elements and poor house design all contribute to the long term performance and durability of cedar siding the most common cause of premature paint failure and cedar siding decay is moisture.

Benefits of Factory Finished Siding:

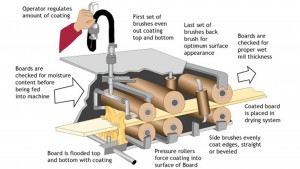

- Using a factory finished siding ensures that the bare wood was primed and painted after it had achieved the proper moisture content by trained factory technicians during the factory coating process. Factory finishing facilities use a primer specifically designed for the given siding or trim product.

- The priming process for factory finished siding ensures that all six side sides of the siding are coated and sealed from moisture.

- Factory finished siding also gives the house an instant painted look after installation.

- Siding can be installed all year round without compromising the quality of the siding finish.

- Factory finish siding reduces the chances of extractive tannin bleeding which also protects the house wrap from degradation.

- Eliminate paint brush lap marks and creates a more uniform finish.

- Factory finished siding is more dimensionally stable and resistant to shrinking.

- A single top coat can last up to 15 years, and two top coats 25 years.

Job site Handling of Factory Finished Siding:

- While waiting to be installed, keep siding loosely covered and off the floor or ground at least six inches, kept out of direct sun or harsh weather.

- Seal all rip and end cuts with a compatible color matched primer.

- Install the siding with stainless steel nails.

- Carefully apply a high quality topcoat as soon as possible but within 90 days.

Using factory finished siding ensures that the siding finish is applied under controlled temperature and humidity conditions and results in an ideal platform for the final topcoat adhesion. When all of the exposed surfaces of the siding are machine finished, expansion and contraction are significantly reduced in the field. The net result is a superior long-lasting finish that greatly reduces future maintenance and provides long term curb appeal.