Dewalt Scroll Saw DW788

Dewalt 20″ Variable-Speed Scroll Saw DW788 Review

Dewalt 20″ Variable-Speed Scroll Saw DW788 Review

Most carpenters would look at today’s scroll saws as a tool used by hobbyists to ply their trade. However, not so long ago these precision machines played an extremely important role in the building of this country. We took a look at the Dewalt Scroll Saw DW788 and came up with some good information for you, especially if your in the market for a scroll saw.

History Of The Scroll Saw

The earliest known scroll saw style blades and frames trace their roots back to Germany and France in the 1500’s. It wouldn’t be until 1829 that the scroll saw would be patented in England and it’s use would become more widespread.

During the Victorian era (1850-1910) the scroll saw would become a vital tool in building adornment in the United States. If you drive around any New England town, you’re bound to see it. Victorian architecture dots our landscape at every turn. On those homes you’ll see the true craftsmanship of a scroll sawyer. From gable brackets to ornamental balustrades, cornice trim to frieze boards. The exterior of these homes hold some of the most beautifully designed “gingerbread” trim.

Not only was the scroll saw used to for exterior purposes on these homes. The interior use of scroll-sawed design was also quite prevalent. Whether it was a decorative transom, ornamental balusters, a piece of fine furniture, or a grandfather clock, that work was all done by a skilled craftsman with a scroll saw.

CNC Router Replacing Scroll Saws?

Fast forward 100 years or so, if you want to change out some rotted ornamental trim on your Victorian era home then a CNC would probably be your answer. Not only is the CNC more accurate than any human being could be, it’s results are also repeatable and quick. What may have taken a week to cut a hundred years ago on the scroll saw, now is done in 30 minutes with a CNC.

Benefits of a Scroll Saw

I have used the scroll saw for about 10 years. The scroll saw has a bunch of benefits for me over a CNC. First, it doesn’t take up much room, and being that my shop is small that is a “big deal” to me. Second, a CNC makes a lot of sawdust, so if you don’t have dust collection then I would say a CNC is not the right choice. Lastly a decent size CNC is a lot more expensive than most scroll saws. So with those things being said, a scroll saw is my tool of choice.

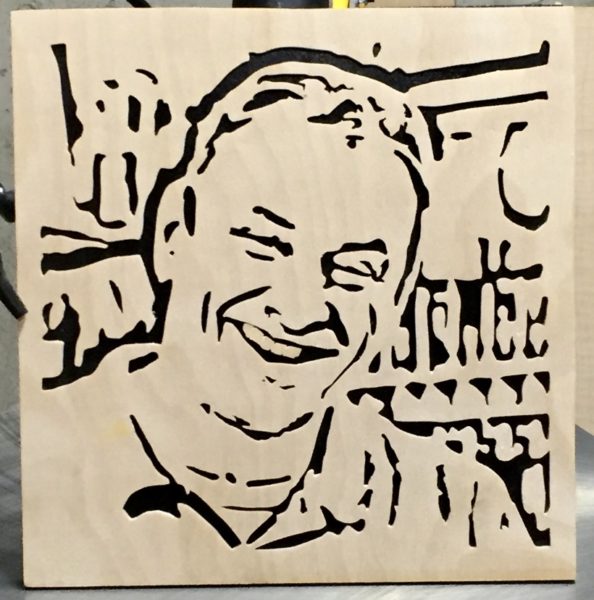

I’ve used a cheap scroll saw for years with some pretty decent results. I’ve made signs, plaques and ornaments for friends, family and even a few customers. I know it won’t make me rich, but it sure is a relaxing way to use your own ideas and truly handcraft something.

Dewalt 20-inchVariable-Speed Scroll saw DW788I

I recently obtained the Dewalt scroll saw #DW788 and the DEWALT scroll saw stand #DW7880, for review.

There are 3 major types of scroll saws on the market today.

- Parallel Arm

- C-Arm

- Parallel Link Arm

The most common is the parallel arm, which uses 2 arms, connected by a rod in the back of the saw to produce a reciprocal motion of the blade. Another type is the C-arm, which, as it name implies, uses a C shaped arm to produce reciprocal blade motion. The last type of saw is the parallel link arm. This type of saw is currently made by 3 companies; Dewalt, Hawk, and Excalibur. Parallel link saws use rods that “push” back and forth, in turn causing 2 parallel links to reciprocate the blade. It has long been known that this type of limited “up and down” movement equals less vibration.

Assembling the Dewalt 20-inch Variable-Speed Scroll saw DW788I

Assembling the saw was quite easy. The only thing that I had to do was attach the table to the saw and secure with a couple screws. The stand took a little more time, due to the number of nuts and bolts that I had to use, but within a half an hour I had everything up and running.

Ensuring Accuracy of the Dewalt Scroll Saw DW788

The first thing I had to do was square the blade to the table. An engineer’s square on the table registered 90 degrees to the blade. The next test was to cut through ¾” stock and check the angle of the cut, again 90 degrees. The last test was the kerf test, where I made a 1” kerf through ¾” stock, shut the saw off, flipped the test piece over and slid the blade down the kerf I had cut. All 3 of these test confirmed the same thing, a perfectly aligned table and blade.

Setting up the Dewalt Scroll Saw DW788

The scroll saw table or surface of the Dewalt #DW788 was perfectly smooth out of the box, and slick like glass, exactly what you’d look for in a scroll saw. The table has a generous 8” in front of the blade and a 20” throat behind the blade, allowing you to work on larger pieces with greater stability. The tabletop will bevel up to 45 degrees to the left and right allowing you to cut inlay or marquetry.

Blade Capacity and Tensioning

This saw only takes 5” plain end blades and they were easily secured in the blade holder with two thumbscrews. Throughout a month of cutting on this saw I have yet to have a blade loosen on me in the holder, which is important when making precise cuts. The blade-tension lever is conveniently placed in the front of the saw on the upper arm. The lever is clearly marked with lines and numbers, making tightening of the blade easy and consistent. It also should be noted that the tension lever can be adjusted while the saw is running. This is a nice feature, where if the blade wasn’t tracking well, you can easily add or release tension as needed without having to stop the saw.

Located just behind the tension knob are the on/off switch, and the speed control. Unlike some other scroll saws, having all the controls up front and within easy reach is definitely a plus. The upper arm on this saw actually can be pivoted up 2” when threading a blade through your work piece to make inside or fret cuts. This scroll saw also has a convenient blower tube mounted to the front of the upper arm. It is easily positioned to keep your cut line clear of dust.

Using the Dewalt 20-inch Scroll Saw DW788I

I’ve used the Dewalt scroll saw #DW788, on three separate projects so far, and it has not disappointed. It is virtually vibration free and quiet. Whether cutting 1/8” Baltic birch plywood or ¾” hard maple, this saw has proven itself as a quality piece of machinery. As noted earlier blade changes and threading of blades was easy and quick, especially tensioning the blade, which is made simple with the marked tension lever.

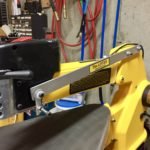

Dewalt Scroll Saw DW788 Stand

The Dewalt Scroll Saw DW788 was what I chose to mount the Dewalt scroll saw #DW788 onto. The stand allows you to keep your saw off your workbench, freeing up space. Out of the box it looked flimsy, but man was I was wrong!

Once I had this stand assembled and the saw mounted on it, I found it to be rock solid. The stand is made to hold the Dewalt Scroll Saw DW788 only, although you may be able to fit other saws on it, I’m unsure if you would have the proper slots/holes in another saws base to fasten it properly. The Dewalt scroll saw’s rear slot and bolt hole were a “little off” so I used a fender washer to make sure that it was fastened down well. The rear leg is adjustable to allow the saw to either sit level or have a 8-degree forward tilt. This adjustment is done during the assembly of the stand and requires the four included bolts and nuts to choose your preferred position. Moving the stand to the other position would require you to disassemble the back leg and reassemble it in that position, so make sure you have it where you want it before you mount your saw, because it’s not that easy.

After reading a little bit about the “tilted position” I chose to set up my stand in that position and I’m glad I did. The forward tilt allows the work to be tilted toward you reducing the amount that you have to bend over to see the work. Whether flat or tilted the scroll saws table top sits at 39” from the floor allowing you a comfortable working height, whether you are standing or sitting on a shop stool. The bottom of the saws stand’s legs each have a bolthole for fastening the stand down to a floor. I chose not to fasten my stand to the floor and have not had any problems with movement or vibration.

Dewalt Scroll Saw DW788 Improvements

All good things have room for improvement and although the Dewalt Scroll Saw DW788 is a solid machine there is definitely some things that could be added or improved to make this saw even better.

If I was cutting marquetry or inlays, I’d much rather have a saw that tilts rather than a table that tilts. This doesn’t mean much to me, but if you are looking into a scroll saw for either one of those styles of cutting exclusively then I would choose another saw.

The material hold-down on this saw is “just OK”. While doing fretwork, I found that due to the saw’s design, I had to loosen the material hold-down every time I retensioned the blade in order to achieve proper tension. On the plus side, it provides a good sight line to your work and was easy to remove, which is exactly what I did.

The upper arm actually lifts up to making threading of the blade through a work piece easier. The problem is if you don’t hold the arm up, it falls back down, which makes it not so easy unless you have three hands. Some people who own this saw actually make a “kickstand” to keep the arm in the up position while they thread the blade. I actually have purchased the “The Lifter” from papasworkshop.org. It is an aluminum arm that easily is added to your existing Dewalt scroll saw #DW788. When lifting the arm to the up position, a hook will latch onto a small peg that is included in the Scroll Saw Lifter kit, holding the arm up. When you have completed threading the blade through the work piece, a gentle lift of the arm while pivoting the hook back will return the arm to the down position.

There are times especially when making complex cuts that both of your hands have to be on the work piece when the scroll blade begins to move. Even though the power switch is at the front of this unit it’s still too far away to start a complex cut.

Deadman Pedal

To take care of this issue I purchased a dead-man pedal. Now when I’m ready to make a tough cut I can have both hands on the piece and pressing down the pedal powers on the machine. In the same respect if I run into a problem, like the blade snapping or a pinched blade that lifts my work piece off the table, dropping my foot off the pedal immediately kills the machine.

Work Light

The Dewalt Scroll Saw DW788 has an optional work light that can be purchased. After checking the specifications on this light I chose not to. This light is outfitted with a 25-watt incandescent bulb. I prefer not to have a hot bulb near my fingers. To solve this issue I purchased a magnet mounted, adjustable, LED sewing machine light. This light easily attaches to the machine, and is cool to the touch.

No Dust Collection

Some scroll saws have dust collection capabilities, most do not. This saw is in the latter category of not having any type of built in dust collection. A 1.3 amp, brushed motor, powers this saw. It is more then enough to make any cut on the scroll saw, and is pretty typical of the size of motor found on a scroll saw. That being said, there is only one manufacturer on the market today that uses an induction style or brushless motor (Hegner). I wouldn’t mind seeing this on my next scroll saw, but it’s not a deal breaker

In conclusion, the Dewalt scroll saw DW788 and Dewalt scroll saw stand DW7880 are both well constructed tools. When paired together will give the serious hobbyist or professional great results on their projects at a decent price point. Although I think there are some improvements that could be made, none of them are reasons to not buy this saw and stand. I know that this saw will be an important part of my workshop for years to come.

Dewalt Scroll Saw #DW788 Specifications

- AMPS 1.3 AMPS

- DEPTH OF CUT (INCHES) 2 IN

- POWER TOOL TYPE CORDED

- STROKE LENGTH 3/4 IN

- STROKES/MIN 400-1,750 SPM

- TOOL WEIGHT 56 LBS

Purchase this unit online here: DEWALT-DW788-20-Inch-Variable-Speed-Scroll