How To Choose The Correct Extension Cord

Choosing the correct extension cord is important to tool and job-site safety.

Extension cords differ in the number and thickness of the wires, the type of plug, and the length of the cord.

Wire thickness:

Extension cord wire thickness determines the amount of power that will be delivered to the tool. Common sizes, or gauges, which are 18, 16, 14, 12 and 10.

Extension cords vary in rating based upon the amperage it can carry, the wattage it can handle, and the gauge of the wire. The smaller the number of wire gauge, the more wattage and amperage it can handle safely.

I use 12 gauge extension cords and keep several lengths of 25′, 50′ and one 100′ cord in my tool trailer.

Length of the cord:

Extension cord length can cause problems. Don’t use a cord that is far longer than what you need, especially if you leave the excess cord coiled. Leaving an extension cord coiled causes heat to build up in the wires which can get hot enough to melt the insulation.

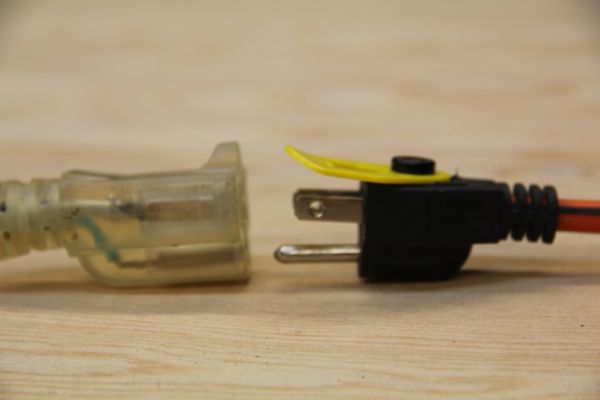

Type of plug:

I recommend always use a three prong, grounded extension cord.

Extension cord lengths 50 feet or less can be used based upon the following chart, but runs over 50 feet should implement the next heavier sized cord to accommodate voltage drop in the cord due to the natural resistance of the wire.

- #18 gauge cord: 5 Amps, 600 Watts: Detail Sander, Drill, Jig Saw

- #16 gauge cord: 7 Amps 840 Watts: Belt Sander, Reciprocating Saw

- #14 gauge cord: 12 Amps 1,440 Watts: Circular Saw, Miter Saw,

- Router

- #12 gauge cord: 16 Amps 1,920 Watts Table Saw, Radial Arm Saw